- Joined

- Aug 31, 2002

- Location

- Buenos Aires, Argentina

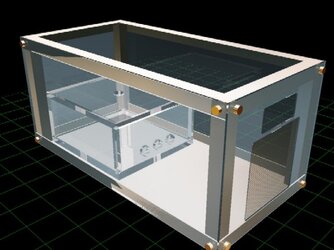

ok, after lots of setbacks, i finally completed my setup.

a nice touch, its that the complete system can be removed without draining the WC.

im using a Shurflo Piranha 500 pump (500 gph), that runs on 12v DC. the heatcore its from an opel corsa. the block its a nice rotor block, with 4.5mm wide 10mm deep holes, with 3/4" hoses. the tank its made with 1cm thick acrylic and it has a 2 liter capacity. the hole system sucks 3 liters of distilled water. i used a radiator aditive called "bardhal" (similar to water wetter and such stuff).

im using 2 Panaflo 12cm H1A fans in a pull push setup, but i havent finished the shroud yet.

here some pics during the leak test.

a nice touch, its that the complete system can be removed without draining the WC.

im using a Shurflo Piranha 500 pump (500 gph), that runs on 12v DC. the heatcore its from an opel corsa. the block its a nice rotor block, with 4.5mm wide 10mm deep holes, with 3/4" hoses. the tank its made with 1cm thick acrylic and it has a 2 liter capacity. the hole system sucks 3 liters of distilled water. i used a radiator aditive called "bardhal" (similar to water wetter and such stuff).

im using 2 Panaflo 12cm H1A fans in a pull push setup, but i havent finished the shroud yet.

here some pics during the leak test.