- Joined

- Aug 6, 2003

- Location

- ---> NEW HOUSE 7/17/09 !! <---

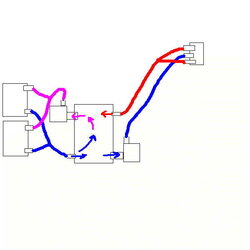

2 loops: 2 pumps; 1 "hot" loop, one "cold" both using the same res....

anyone tried this B4?

anyone who understands the rules of fluid dynamics have any ideas/thoughts? (J/K )

)

my thoughts: the different restrictions of the 2 loops (***-u-me the same pump) will make this 2x as complicated!

is this worth kicking around?

im THINKING of using some/all of this: parts in my sig [NOT the TEC!(yet) or slitedge] + Caprice core, chevette core, Dtech WW, 2nd Mag3 (maybe Eh. 1250), DIY res (1 gal.)

anyone tried this B4?

anyone who understands the rules of fluid dynamics have any ideas/thoughts? (J/K

my thoughts: the different restrictions of the 2 loops (***-u-me the same pump) will make this 2x as complicated!

is this worth kicking around?

im THINKING of using some/all of this: parts in my sig [NOT the TEC!(yet) or slitedge] + Caprice core, chevette core, Dtech WW, 2nd Mag3 (maybe Eh. 1250), DIY res (1 gal.)

)

)