-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ANY problems with Hydor L30, pls post here !

- Thread starter dinster

- Start date

- Joined

- May 29, 2002

- Location

- Japan/Daytona Beach

the majority of the problems people complain about are user error .

i myself have caused problems with a L30 1

the problem is that people open them and when they put the impellor back in they do it wrong which leads to an improper seat whci leads to it vibrating free then scratching the impellor magnet against the rest of the motor.

a lot of people try and say that isnt what happend but it is usualy the case.

i myself have caused problems with a L30 1

the problem is that people open them and when they put the impellor back in they do it wrong which leads to an improper seat whci leads to it vibrating free then scratching the impellor magnet against the rest of the motor.

a lot of people try and say that isnt what happend but it is usualy the case.

- Joined

- Jan 15, 2004

my threaded barbs and my tubing didnt like eachother, so it leaked. In short I had to get new threaded barbs and now it works. Nothing else besides that

- Joined

- May 12, 2004

you shud get the hydor L35 jus a few bux more

- Joined

- May 29, 2002

- Location

- Japan/Daytona Beach

besides me who actualy has a L35?you shud get the hydor L35 jus a few bux more

i have yet to see a single person with one .

- Joined

- Nov 25, 2003

- Thread Starter

- #8

AngryAlpaca said:Have you considered a Mag 3? It's cheap and it's good. It has a minor leak, but that is easily fixed.

thanks for ur advice.. the problem is Mag 3 is not available here in Malaysia..

the only choice i have now is L30, both Eheim 1250 and 1048..

yeah.. i can buy the Mag 3 here.. but the input voltage is different.. 120V..

- Joined

- Mar 7, 2004

- Location

- Los Angeles

Hmmm, well here's my $.02 pumpwise.

I personally like DC watercooling pumps, and here's my reasons why

-Convience. I dont want to have to drill a hole through my case or get a relay for my pump to even work with my computer, let alone add another plug to my already crowded powerstrip, so I personally favor a simple pump that can just be plugged into a molex connector.

-Noise. Direct Current (DC) motors are generally quieter than Alternating Current (AC) motors.

-Looks. With the exception of the Laing D4, I personally think DC pumps look better than AC pumps just because they can be smaller (and are usually meant for watercooling too)

-Warranty. Most pumps meant for watercooling (MCP600 Rev. 2, AquaXtreme) have a 2 year warranty. I dont think the Mag3 has a warranty like that.

That's my viewpoint on pumps, however if you must go with the hydor L30, I've heard it's pretty good. I haven't heard of many L30's failing. See if you can find an L35 somewhere, as they're probably better than the L30.

I personally like DC watercooling pumps, and here's my reasons why

-Convience. I dont want to have to drill a hole through my case or get a relay for my pump to even work with my computer, let alone add another plug to my already crowded powerstrip, so I personally favor a simple pump that can just be plugged into a molex connector.

-Noise. Direct Current (DC) motors are generally quieter than Alternating Current (AC) motors.

-Looks. With the exception of the Laing D4, I personally think DC pumps look better than AC pumps just because they can be smaller (and are usually meant for watercooling too)

-Warranty. Most pumps meant for watercooling (MCP600 Rev. 2, AquaXtreme) have a 2 year warranty. I dont think the Mag3 has a warranty like that.

That's my viewpoint on pumps, however if you must go with the hydor L30, I've heard it's pretty good. I haven't heard of many L30's failing. See if you can find an L35 somewhere, as they're probably better than the L30.

- Joined

- Nov 25, 2003

Oh. If you're in Malaysia and can't afford the Eheims, go for the Hydors. I have not heard of problems with them.

Ever listen to a D4?-Noise. Direct Current (DC) motors are generally quieter than Alternating Current (AC) motors.

The D4 makes up a good percentage of the DC pumps... Yes, the MCP600 does look nice, I'll admit.-Looks. With the exception of the Laing D4, I personally think DC pumps look better than AC pumps just because they can be smaller (and are usually meant for watercooling too)

There's no such thing as a pump built for watercooling.-Looks. With the exception of the Laing D4, I personally think DC pumps look better than AC pumps just because they can be smaller (and are usually meant for watercooling too)

The Mag 3 has a 3 year warranty.-Warranty. Most pumps meant for watercooling (MCP600 Rev. 2, AquaXtreme) have a 2 year warranty. I dont think the Mag3 has a warranty like that.

- Joined

- May 6, 2004

- Location

- Spain

thorilan:

so which is the correct way to place the impeller back??

(i might be one of those u mentioned )

)

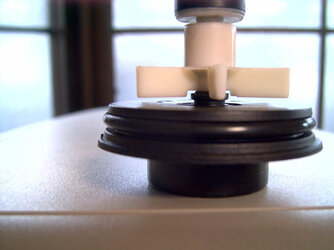

I had a problem with my pump not working. I had to take the impeller off to see what happened and realized that the magnet-impeller thing couldn't move freely around the metal bar. Also realized that the white plastic thing (where u put the impeller) which goes into the magnet hole was not glued and could be moved away from the magnet as u see in the pic. Should I glue it to the magnet? (guess so).

Now after taking the thing off, the metal bar can be introduced through the magnet-impeller hole so the magnet-impeller can spin freely around the bar. Before, the bar was somehow fixed, so the magnet-impeller couldnt spin, unless the full set spined, but the bar is fixed to the pump by the endcaps so... thats why it couldnt spin.

So my questions are:

Can u move freely the magnet-impeller set over the metal bar in ur pump?

Is your white plastic thing glued to the magnet?

Sorry If I couldn't explain it better.

seeya

so which is the correct way to place the impeller back??

(i might be one of those u mentioned

I had a problem with my pump not working. I had to take the impeller off to see what happened and realized that the magnet-impeller thing couldn't move freely around the metal bar. Also realized that the white plastic thing (where u put the impeller) which goes into the magnet hole was not glued and could be moved away from the magnet as u see in the pic. Should I glue it to the magnet? (guess so).

Now after taking the thing off, the metal bar can be introduced through the magnet-impeller hole so the magnet-impeller can spin freely around the bar. Before, the bar was somehow fixed, so the magnet-impeller couldnt spin, unless the full set spined, but the bar is fixed to the pump by the endcaps so... thats why it couldnt spin.

So my questions are:

Can u move freely the magnet-impeller set over the metal bar in ur pump?

Is your white plastic thing glued to the magnet?

Sorry If I couldn't explain it better.

seeya

Attachments

Last edited:

- Joined

- May 25, 2004

- Location

- Pacific NW

I had an L30 as my first pump, but I ended up switching to an MCP600 within a month because the noise that the pump was causing was driving me nuts. I had never taken the pump apart, and had it well cushioned by 1/2" pieces of foam, but the thing still made a rattling noise that was audible over my fans at 2000 RPM.

Once I switched to the Swifty, I could turn my fans down to 1200 RPM and still not hear the pump.

Of course, then the Swifty decided to stop working all of a sudden...

Guess I just don't have very good luck with pumps.

Once I switched to the Swifty, I could turn my fans down to 1200 RPM and still not hear the pump.

Of course, then the Swifty decided to stop working all of a sudden...

Guess I just don't have very good luck with pumps.

- Joined

- Apr 19, 2003

I've been running an L30 for about 18 months now without any trouble. It's quite quiet as long a it is mechanically isolated from the surface upon which it is mounted. The stock suction cups or a piece of foam are adequate for this purpose.

- Joined

- May 29, 2002

- Location

- Japan/Daytona Beach

ok for mavrick . you didnt take a pic of the most important parts together.

btw you shouldnt ever have to take the impellor blades off the axle

.the key to doing the mounting correctly is to make sure that the impellor and axle are mounted onto the black intake plastic correctly

ill post a pic in a few min

you want the the impellor very firmly seated into it with the impellor blades perfectly level and equal distantce on all sides from the flat surface of the intake peice.

btw you shouldnt ever have to take the impellor blades off the axle

.the key to doing the mounting correctly is to make sure that the impellor and axle are mounted onto the black intake plastic correctly

ill post a pic in a few min

you want the the impellor very firmly seated into it with the impellor blades perfectly level and equal distantce on all sides from the flat surface of the intake peice.

Attachments

- Joined

- May 29, 2002

- Location

- Japan/Daytona Beach

almost everyone i have talked to has put the impellor in first then put the black plastic intake on over it.

- Joined

- May 6, 2004

- Location

- Spain

please answer me to some questions.

1. can u move the impeller-magnet set freely over the metal bar?? (so it can spin AROUND the bar and not WITH the bar) I hope u know what I mean.

2. Is the white plastic thing glued to the magnet in ur pump? (see in my pic what I mean by "white plastic thing" )

)

Thx

1. can u move the impeller-magnet set freely over the metal bar?? (so it can spin AROUND the bar and not WITH the bar) I hope u know what I mean.

2. Is the white plastic thing glued to the magnet in ur pump? (see in my pic what I mean by "white plastic thing"

Thx

- Joined

- May 29, 2002

- Location

- Japan/Daytona Beach

1 yes they are not joined and the magnet rotates while the bar stays in place

the impellor blades on mine are not glued but they are a tight fit so that there is not much movement without force . i could glue it but havent needed to

the impellor blades on mine are not glued but they are a tight fit so that there is not much movement without force . i could glue it but havent needed to

- Joined

- May 6, 2004

- Location

- Spain

yeah the impeller blades are not glued, i mean the rest of the white plastic, where u put the impeller.

thx so much for ur help

thx so much for ur help

- Joined

- Dec 20, 2003

- Location

- London, England

dinster said:thanks for ur advice.. the problem is Mag 3 is not available here in Malaysia..

the only choice i have now is L30, both Eheim 1250 and 1048..

yeah.. i can buy the Mag 3 here.. but the input voltage is different.. 120V..

iirc malaysia is 50hz AC?

dinster?

thorilan said:ok for mavrick . you didnt take a pic of the most important parts together.

btw you shouldnt ever have to take the impellor blades off the axle

.the key to doing the mounting correctly is to make sure that the impellor and axle are mounted onto the black intake plastic correctly

ill post a pic in a few min

you want the the impellor very firmly seated into it with the impellor blades perfectly level and equal distantce on all sides from the flat surface of the intake peice.

Because it's a big magnet dosen't it just pull it out of the cover when you insert it back into the pump? That's the probs that i had with mine. i'm thinking i shouln't have sealed the heck out of it though..

Similar threads

- Replies

- 9

- Views

- 669

- Replies

- 7

- Views

- 891

- Replies

- 20

- Views

- 2K