- Joined

- May 20, 2004

So I have spent the last week on furious runs to Home Depot and back, working late into the night in my garage, waking neighbors with oscillating sanders and what not.

I will now unveil the result. My first real attempt at any kind of handywork, and I hope you all will like it. I'd like to thank Yelgnid, who helped get my thoughts rolling.

So first I'll introduce the cast:

Tools:

*Oscillating Sander (wonderful tool, little handheld thing that sure beats the heck out of elbow grease)

*Handheld Jigsaw

*Power drill/screwdriver

*Plastic Scorer - special hooked razor blade for scoring plexi glass so you can cut it. ~$2 at Home Depot.

*C Clamps (love 'em!)

*Breaking Shears (from stained glass work, but they work great to help finish off a plexi glass cut)

*maybe more I'm forgetting now

Materials:

*1 board of 3/4" thick Eastern Pine cut to the sizes I had planned out

*1 1/2" MDF board for top and bottom

*Wipe-On Clear Gloss Polyurethane

*1 sheet plexi glass

*silicone seal

*1-5/8" screws (and some 1-1/4")

*hinges

*latches

*L brackets and various metal strips

*Weather stripping

I'm going to have to attach all the pics, as I don't have a hosting site. Sorry!

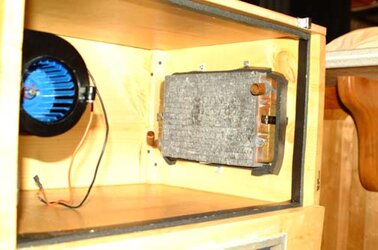

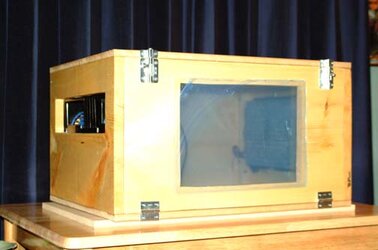

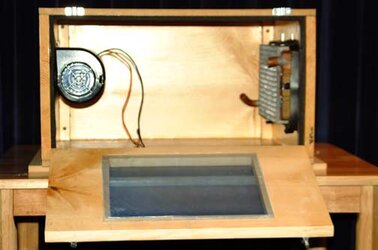

Here are all of the boards with the inside holes cut. the small one is for my 540cfm blower, the middle one is for a Fedco 2-342 HC, and the large one is for the window I'm installing.

All of these boards were thoroughly sanded and then had 2-3 coats of a wipe-on polyurethane applied. you have to lightly sand inbetween coats for optimal smoothness.

I will now unveil the result. My first real attempt at any kind of handywork, and I hope you all will like it. I'd like to thank Yelgnid, who helped get my thoughts rolling.

So first I'll introduce the cast:

Tools:

*Oscillating Sander (wonderful tool, little handheld thing that sure beats the heck out of elbow grease)

*Handheld Jigsaw

*Power drill/screwdriver

*Plastic Scorer - special hooked razor blade for scoring plexi glass so you can cut it. ~$2 at Home Depot.

*C Clamps (love 'em!)

*Breaking Shears (from stained glass work, but they work great to help finish off a plexi glass cut)

*maybe more I'm forgetting now

Materials:

*1 board of 3/4" thick Eastern Pine cut to the sizes I had planned out

*1 1/2" MDF board for top and bottom

*Wipe-On Clear Gloss Polyurethane

*1 sheet plexi glass

*silicone seal

*1-5/8" screws (and some 1-1/4")

*hinges

*latches

*L brackets and various metal strips

*Weather stripping

I'm going to have to attach all the pics, as I don't have a hosting site. Sorry!

Here are all of the boards with the inside holes cut. the small one is for my 540cfm blower, the middle one is for a Fedco 2-342 HC, and the large one is for the window I'm installing.

All of these boards were thoroughly sanded and then had 2-3 coats of a wipe-on polyurethane applied. you have to lightly sand inbetween coats for optimal smoothness.

Attachments

Last edited: