- Joined

- Nov 20, 2003

- Location

- Sydney Australia

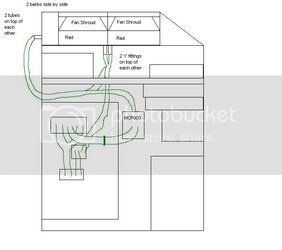

Ok, I've bought this up in this forum a while back, but this is proboby it and im gonna take design to the plastics workers within this week (i cant mod well worth a crap and also, no tools). So here are my designs, i transferred from paper to paint cuz im too cheap to get a scanner. A few sketches couldnt be transferred cuz my paint skillz are just too crap, but i'll try my best to explain it.

This reservoir is going to be put on top of a Thermaltake Xaser III V2000A case and is meant to be a multi function piece. It is built around two JR-120 radiators, meant to hold 2 120mm fans and to keep the fans a certain distance away from the radiators to act as a sort of shroud.

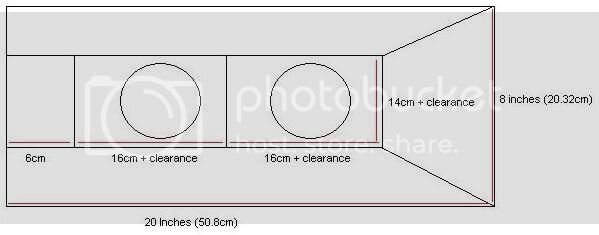

Top view:

The top of the Xaser III case measures exactly 20 inches long by 8 inches wide and the reservoir was meant to cover the entire thing.

The front and sides are meant to be slanted whilst the back is one flat piece. The two circles are holes is the places where the fans can blow air out.

In between the two radiators, there is going to be a dividing piece, so that each radiator and fan combo is going to have it's own airtight box, separate from each other.

The barb positions are still not decided but i'll talk about that dilemma later.

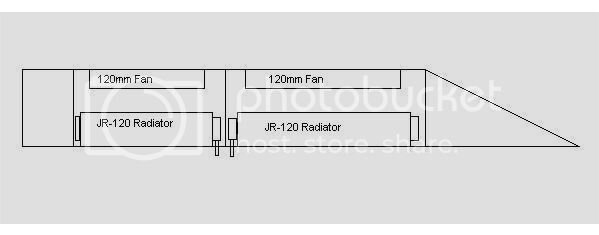

Side View (from left):

This further clarifys my illustration on how the radiators and fans are meant to be mounted as well as the shape.

The fan is exactly 2.5cm tall and the radiator is exactly 2 inches or about 5cm tall. For the space between the fan and the radiator: im not sure, im thinking about 0.75 of an inch or maybe 2cm, around that ballpark figure. Anyone have any ideas about this?

So the height of the reservoir is going to be 5cm + 2.5cm + (distance between fan and radiator) + thickness of acrylic. So maybe about 10cm give or take?

Major Problem:

Where do i put the barbs?

Initially, i thought i could put them in the bottom sides, but it turned out that we were talking a width of about 2-3cm. Even if i managed to get the barb for my 1/2" ID system in, it might leave the acrylic very prone to cracking.

The length of my power supply is 14cm and the distance between the top of the PSU and the top of the case is about 5cm, so im gonna need some 90 degree elbows built into the reservoir if im putting the input and output of the res at the rear.

The length of my shortest Optical drive is 15cm and since my Hardcano that came with the case is kinda empty, the distance between the top of the optical drive and the top of the case is 5.8cm. The barb will fit if i put the barb at the front, but my hose wont bend like that.

An idea i have is maybe putting the barbs right at the back so that they're external and having the tubes lead back into the case via holes above the IO shield.

Any suggestions on this one?

Im going to be building this entire thing out of thick Acrylic. Polycarbonate is probobly out of the question, in HK, hardly anyone knows how to join Polycarbonate reliably since there's no solvent available for it here. If there is, it's probobly going to be prohibitably expensive.

Comments anybody?

As soon as it's made up, pics are going to be up.

This reservoir is going to be put on top of a Thermaltake Xaser III V2000A case and is meant to be a multi function piece. It is built around two JR-120 radiators, meant to hold 2 120mm fans and to keep the fans a certain distance away from the radiators to act as a sort of shroud.

Top view:

The top of the Xaser III case measures exactly 20 inches long by 8 inches wide and the reservoir was meant to cover the entire thing.

The front and sides are meant to be slanted whilst the back is one flat piece. The two circles are holes is the places where the fans can blow air out.

In between the two radiators, there is going to be a dividing piece, so that each radiator and fan combo is going to have it's own airtight box, separate from each other.

The barb positions are still not decided but i'll talk about that dilemma later.

Side View (from left):

This further clarifys my illustration on how the radiators and fans are meant to be mounted as well as the shape.

The fan is exactly 2.5cm tall and the radiator is exactly 2 inches or about 5cm tall. For the space between the fan and the radiator: im not sure, im thinking about 0.75 of an inch or maybe 2cm, around that ballpark figure. Anyone have any ideas about this?

So the height of the reservoir is going to be 5cm + 2.5cm + (distance between fan and radiator) + thickness of acrylic. So maybe about 10cm give or take?

Major Problem:

Where do i put the barbs?

Initially, i thought i could put them in the bottom sides, but it turned out that we were talking a width of about 2-3cm. Even if i managed to get the barb for my 1/2" ID system in, it might leave the acrylic very prone to cracking.

The length of my power supply is 14cm and the distance between the top of the PSU and the top of the case is about 5cm, so im gonna need some 90 degree elbows built into the reservoir if im putting the input and output of the res at the rear.

The length of my shortest Optical drive is 15cm and since my Hardcano that came with the case is kinda empty, the distance between the top of the optical drive and the top of the case is 5.8cm. The barb will fit if i put the barb at the front, but my hose wont bend like that.

An idea i have is maybe putting the barbs right at the back so that they're external and having the tubes lead back into the case via holes above the IO shield.

Any suggestions on this one?

Im going to be building this entire thing out of thick Acrylic. Polycarbonate is probobly out of the question, in HK, hardly anyone knows how to join Polycarbonate reliably since there's no solvent available for it here. If there is, it's probobly going to be prohibitably expensive.

Comments anybody?

As soon as it's made up, pics are going to be up.