I will be building a water cooling system soon, just want to make sure I am on the right track as far as design goes:

From what I can gather it seems that the general consensus is that wide tube diameter in water cooling systems is good, so I would be using 10 - 12mm diameter tubes within the system.

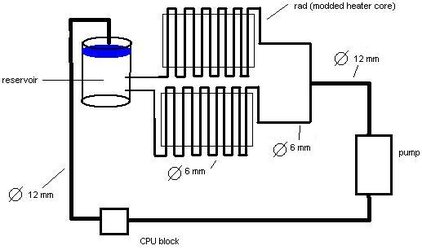

The heater cores available to me to make a radiator seem to consist of tube roughly 6mm in diameter. I intend to convert heater cores into single-pass radiators.

Because of the conflict in tube diameters, I had the idea of connecting 2 radiators in parallel, and to split the flow between them to avoid the problem a single radiator would have on flow due to differing tube sizes.

Attached (hopefully, if it worked) is an image of the design... would connecting 2 radiators in this way cause problems with flow rate or system pressure?

From what I can gather it seems that the general consensus is that wide tube diameter in water cooling systems is good, so I would be using 10 - 12mm diameter tubes within the system.

The heater cores available to me to make a radiator seem to consist of tube roughly 6mm in diameter. I intend to convert heater cores into single-pass radiators.

Because of the conflict in tube diameters, I had the idea of connecting 2 radiators in parallel, and to split the flow between them to avoid the problem a single radiator would have on flow due to differing tube sizes.

Attached (hopefully, if it worked) is an image of the design... would connecting 2 radiators in this way cause problems with flow rate or system pressure?