- Joined

- Jun 16, 2003

- Location

- Cranberry Twp. PA

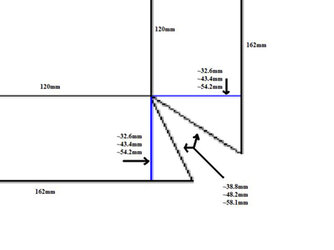

It's for a shroud. I'm trying to find the degree I need to sweep in from the outside of the rad to the outside of the fan. Everything is in MM 'cause metric rocks for measurements and imperial is total ****.

This is wrong, see below:

105mm depth

core side - 162mm

fan side - 120mm

difference - 38mm

difference/side of core-to-fan - 19mm

tan0 (theta) =o/a

tan0 = depth/difference-per-side

tan0=105/19

tan0=5.526 degrees sweep

correct?

This is wrong, see below:

105mm depth

core side - 162mm

fan side - 120mm

difference - 38mm

difference/side of core-to-fan - 19mm

tan0 (theta) =o/a

tan0 = depth/difference-per-side

tan0=105/19

tan0=5.526 degrees sweep

correct?

Last edited: