- Joined

- Dec 29, 2003

- Location

- Israel

first the update : i found a rad  a big one 60*30*3 CM more or less

a big one 60*30*3 CM more or less

not in a perfect condition but it can be fixed, pics in ~24 hour.

it waz found on my way to school , it's even black

now for my problem now.

i am very close to get me some good toolz.

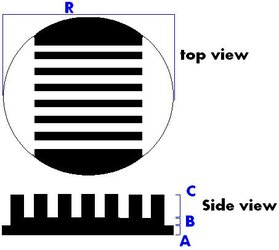

i need to know one final thing before the make of the blokz.

what size to make them>?

i want them to sit perfectly on:

A64 , NF4 ultra NB , GF6600GT.

what size? 5*5Cm for cpu? 3*3 for NB?

plz hlp

a big one 60*30*3 CM more or less

a big one 60*30*3 CM more or lessnot in a perfect condition but it can be fixed, pics in ~24 hour.

it waz found on my way to school , it's even black

now for my problem now.

i am very close to get me some good toolz.

i need to know one final thing before the make of the blokz.

what size to make them>?

i want them to sit perfectly on:

A64 , NF4 ultra NB , GF6600GT.

what size? 5*5Cm for cpu? 3*3 for NB?

plz hlp

Last edited: