- Joined

- Dec 26, 2004

- Location

- Philadelphia

I read that you are reaching the limit on the storm and was wondering if you tried this design out.

This is a picture you have as the storm g7

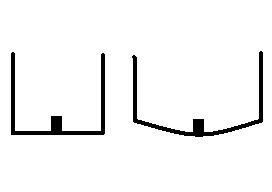

What if you cut slits in between each cup? Do you think it's improve the flow or block itself. Here is a pic of what I mean.

This is a picture you have as the storm g7

What if you cut slits in between each cup? Do you think it's improve the flow or block itself. Here is a pic of what I mean.