TreeNode said:

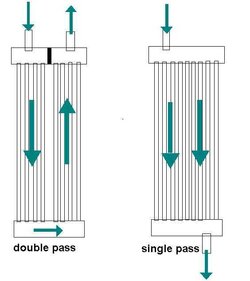

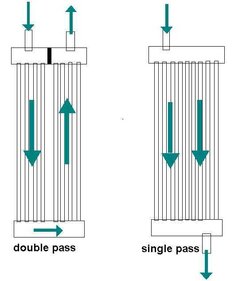

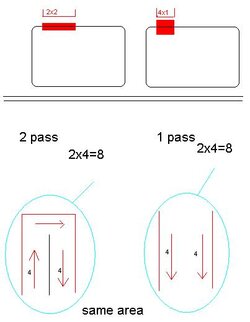

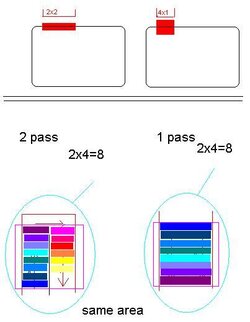

Its more like XFlow has higher flow rates while 2-pass (dual row) rads allow the water to stay in the rad longer to cool off more. But, if you consider them side by side with the same pump, an XFlow system would work better with a lower powered pump than a 2-pass rad. With a high powerful pump, a 2-pass would be better.

you have to be very carefull here . you are heading the wrong direction and are about to mislead people into popular urban cooling legend

water stays in a rad the same amount of time in a closed loop weather its single or dual pass so flow is always the most important. while technically if you ONLY count a SINGLE revelution in the cycle ONLY keep in mind , THEN AND ONLY THEN is it possible for water to pick up more heat from a dual rad.

( does not include relationship between DT because its only a single cycle)

once you establish that water cooling is a closed loop and will

REcycle meaning make more than 1 pass through the loop, you have just established that water will spend the same amount of time in the rad.

how this relates to efficiency is the DELTA T

you want your DT to be as efficient as possible aka as wide as possible.

that means the diference between the hot and cold basically. which will cool a hot frying pan better ? 1 liter per minute of tap water or 1 liter per minute of ice water?

ice water of coarse. so to let water stagnate inside a 2 pass rad is going to be less efficient. your ice water just warmed up and is not making any room for new ice water to come in..

if this is confusing you need to review that this is a closed loop in which the distance the water travels is always the same and the amount of water is the same. .

a race track... say you have a race track and you go 5 miles an hour around the track ( slow flow). you go around a 1 mile track in 12 minutes . its still 1 mile though.

NOW go around a race track at 60 miles per hour . you just went 1 mile in 1 minute. YOU STILL ONLY WENT 1 MILE . you did it 12x as fast ( high flow).

but you picked up more heat ( more than slow flow) because your ice water was FRESHER ( spent less time and kept the Delta T here after called Dt,

WIDER). this is where spead aka flow creates efficiency.

TreeNode said:

Though, this is not even considering the flowrates through the blocks and hose length which will alter things. If you have restrictive blocks, you can't possibly get the water circulating the "right way" through an XFlow anyhow so you would go with a 2-pass to balance it out.... etc.

now this is just ... i dont know.. i cant see what you are trying to demonstrate.

maybe if you re word it i can figure out what you are trying to say.

pumps are rated to work in efficncy with certain head ratings at certian speeds. so some pumps are like a slow moving wide deep river . they have more force behind them but they are not moving as fast

BUT they overcome minor restriction better so that it does not slow their flow

FURTHER .

high flow low head pumps are the oposite like a shallow stream that runs at much higher speeds ( or velocity if you like big words). the problem is they are reduced in speed very easily by restriction so thier speed could slow down a LOT more .

so if i have a pump that pumps 10 gallons a minute and its low power and the restriction slows its speed down to 2 gallons per minute it will not be as effective as a higher head pump that pumps max speed of 6 gallons a minute but WITH restriction only pumps 3 gallons . basically the higher head overcame the resitance more effectively to have an over all higher flow to restriction rate..( these are demonstration synthetic numbers only , not based on any particular pump)

this is where choosing your pump is important . some people over do the pump they need in either to high a flow or to high a head for thier system . its a HUGE balancing act where you haev to match your block and rad ( with Fan ) to the right pump for you.

ways to manage the balancing act .

reduce restriction through shorter tubing runs

reduce restriction through less bends in the loop ( this includes going from dua l pass to single pass)

use a pump that is suited to the systems OVERALL restriction require ment and keeps the flow near the water blocks most efficient speed( this also balances the speed vs deminished returns)

balance everything vs noise and stable OC (aka how much bleeding ears are you willing to put up with)

some hints that i dont usually give system designers but might as well.

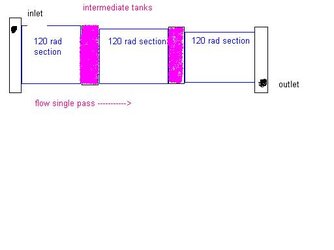

you can eliminate tubing lenght by using VERTICALLY mounted single pass cores .

keep the pump at the BOTTOM of the loop so that the pump outlet is very close to the

core bottom inlet ( this should reduce a large portion of tubing)

the cores

outlet should sit just below the water block inlet so that water is still traveling in an upward movement( this bleeds the system as air travels up and

with flow not against it)

from your water block you should have a VERTICALLY mounted res or air trap/tline that travels straight down to the pump inlet ( the res acts as both res air trap and tubing emoving even more tubing from the loop)

note that a good res will be tall and skinny with the water INLET slight below the fill opening BUT still higher than the OUTPUT of the water block so that air travels out of the block UPWARDS into the res where it travels to where you fill the res

it literally takes me under 1 minute to completely fill and bleed a system 100%.

your bigest problem with the design is the case. thats why i prefur tall lian li cases for this.