- Joined

- Feb 21, 2006

- Location

- Oklahoma City

I want to use a geothermal cooling loop for my watercooling rig. My reasons are simple: Less mess in the house and less heat being blown around the house. South Texas summers are brutal and I don't want my computer to fight my A/C.

I plan on burying the loop 4' underground. I know that deeper would be better, but I would not be able to dig down deeper. This depth should be more than adequate for my purposes.

I have two designs for the radiators.

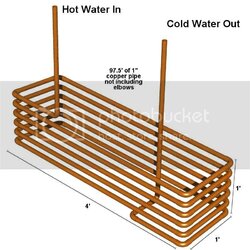

The first is a simple helix design. All 1" copper pipe and fittings.

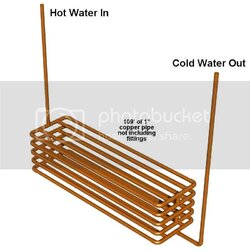

The second is a bit more complicated and has more copper. Again, all 1" pipe and fittings. In this design, water cascades down from the upper tier to the lower tiers.

Which would be better? I would assume design #2 because of the added copper and surface area. However, that would be a pain in the butt to build.

Does anyone have experiance with this? Any thoughts?

Thanks,

Mark

I plan on burying the loop 4' underground. I know that deeper would be better, but I would not be able to dig down deeper. This depth should be more than adequate for my purposes.

I have two designs for the radiators.

The first is a simple helix design. All 1" copper pipe and fittings.

The second is a bit more complicated and has more copper. Again, all 1" pipe and fittings. In this design, water cascades down from the upper tier to the lower tiers.

Which would be better? I would assume design #2 because of the added copper and surface area. However, that would be a pain in the butt to build.

Does anyone have experiance with this? Any thoughts?

Thanks,

Mark