- Joined

- Oct 26, 2004

- Location

- Bay Area, CA

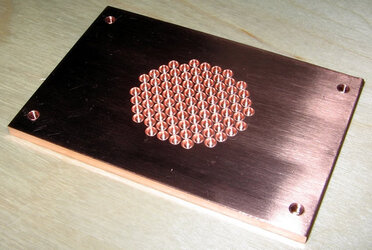

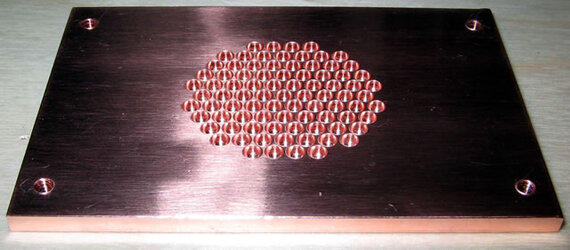

Here's my latest project (and eventually product). After considering a number of different designs the engineers I have been working with felt a high density jet impingement design would provide the best performance. The current Swiftech STORM block is the overall performance leader, but it's design has been eclipsed by Cathar's next generation STORM G7 - though a part has yet to reach the market. Understandably the machining costs are dramatically higher to manufacture a successor to the comparitively simple G5.

This new waterblock, which will likely be called the NCX-1 has been designed from the ground up to deliver unbeatable cooling for today's larger CPU's. Featuring 85 impingement jets covering a larger surface area projected performance values are well above current levels. For maximum efficiency the thickness of the base at the bottom of the jet pockets is only .025" (0.635 millimeters).

The midplate has been designed to minimize headloss and crossflow and will be manufactured from Acetal (Delrin).

The top will be machined from Acetal and willl sport 1/2" NPT or BSP threading.

Once the first units are completed, they will be sent out to various reviewers (including Joe Citarella).

I expect to have the first dozen samples ready by the end of the month. CPU compatibility is: All AMD Socket 939, 940, AM2 and Intel Socket 478, LGA775.

I'll keep putting up pictures as each stage is completed. Please feel free to leave whatever feedback or suggestions.

This new waterblock, which will likely be called the NCX-1 has been designed from the ground up to deliver unbeatable cooling for today's larger CPU's. Featuring 85 impingement jets covering a larger surface area projected performance values are well above current levels. For maximum efficiency the thickness of the base at the bottom of the jet pockets is only .025" (0.635 millimeters).

The midplate has been designed to minimize headloss and crossflow and will be manufactured from Acetal (Delrin).

The top will be machined from Acetal and willl sport 1/2" NPT or BSP threading.

Once the first units are completed, they will be sent out to various reviewers (including Joe Citarella).

I expect to have the first dozen samples ready by the end of the month. CPU compatibility is: All AMD Socket 939, 940, AM2 and Intel Socket 478, LGA775.

I'll keep putting up pictures as each stage is completed. Please feel free to leave whatever feedback or suggestions.

Last edited: