Routing tubing in that fashion wouldn’t be any easier than the current method, and wouldn’t provide any real benefit. That’s probably why it isn’t done.

Turbulence is a tricky thing. There’s not a lot of it in PC water-cooling. Even the Storm waterblock, arguably the most turbulent design, has less turbulence than water running through 1/2" tubing. So maximizing turbulence is not as important in water-cooling as most people think.

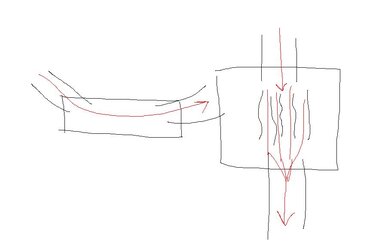

What IS important is to get as many water molecules in contact with hot copper as is possible. This is actually very difficult. In a water-cooled waterblock, the area that gets hot is fairly small. Also, if you don’t have a defined entry-exit path then the water tends to get in its own way and not flow well. The reason why the Storm works well is because water has a well-defined path into and out of each cup, which results in more water molecules coming in contact with hot copper.

A block that performs as well as the Storm...the Hydrocool Hydro-Stream HS5...works by squeezing water through very narrow tubes, thereby maximizing the number of water molecules that touch the hot parts of the block. The design has a very high pressure drop, however.

In designs such as yours what ends up happening is that a large amount of water will flow over the top of the hot areas and not actually come in contact with the hot copper. If you reduce the channel size to increase contact then you have pressure issues, like the Hydro-Stream.

So the path to better cooling isn’t blocked by 90-degree bends or lack of turbulence, but by the difficulty of creating low-restriction designs that maximize water contact with the hot parts of the block. Currently, the Storm represents the best of that design.