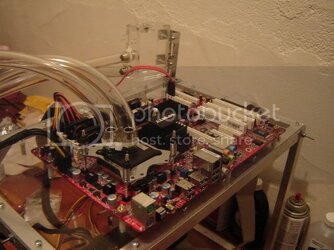

It's coming up on a year since I last drained and refilled my system. Even though the tubing looks as clear as the day I installed it and the fluid still looks good, I like to replace the tubing and fluid every year just to be safe. Since I'll be taking the system apart, I decided to buy a Fuzion to replace my Apogee (the one before that started calling it the Apogee GT). I haven't purchased the new tubing yet because I remembered a member here complaining about 1/2 ID 3/4 OD tubing with clamps barely fitting on the Fuzion. I had some leftover tubing and decided to try it on the Fuzion before I bought new tubing. After sliding one tube on, I actually had trouble slipping the second one over the other barb! There is absolutely no room to get a hose clamp on  So I guess I'll have to use 7/16 ID 5/8 OD tubing on it. I really don't want to use 7/16 for the whole loop because of the pain it would be to get the tubing on the plastic barbs on the Swiftech MicroRes. Would it hurt the flow if I mixed 7/16 with 1/2 tubing in the loop? I would have 7/16 coming out of the MCP655 to the inlet on the Fuzion, and then from the outlet on the Fuzion to the inlet on EK-FCX1900 GPU block. Everything else would be 1/2 tubing.

So I guess I'll have to use 7/16 ID 5/8 OD tubing on it. I really don't want to use 7/16 for the whole loop because of the pain it would be to get the tubing on the plastic barbs on the Swiftech MicroRes. Would it hurt the flow if I mixed 7/16 with 1/2 tubing in the loop? I would have 7/16 coming out of the MCP655 to the inlet on the Fuzion, and then from the outlet on the Fuzion to the inlet on EK-FCX1900 GPU block. Everything else would be 1/2 tubing.

So I guess I'll have to use 7/16 ID 5/8 OD tubing on it. I really don't want to use 7/16 for the whole loop because of the pain it would be to get the tubing on the plastic barbs on the Swiftech MicroRes. Would it hurt the flow if I mixed 7/16 with 1/2 tubing in the loop? I would have 7/16 coming out of the MCP655 to the inlet on the Fuzion, and then from the outlet on the Fuzion to the inlet on EK-FCX1900 GPU block. Everything else would be 1/2 tubing.

So I guess I'll have to use 7/16 ID 5/8 OD tubing on it. I really don't want to use 7/16 for the whole loop because of the pain it would be to get the tubing on the plastic barbs on the Swiftech MicroRes. Would it hurt the flow if I mixed 7/16 with 1/2 tubing in the loop? I would have 7/16 coming out of the MCP655 to the inlet on the Fuzion, and then from the outlet on the Fuzion to the inlet on EK-FCX1900 GPU block. Everything else would be 1/2 tubing.