- Joined

- Dec 29, 2007

- Location

- Noo Joisey

Anubis is named after the Egyptian God that's a guardian of the dead. Why Anubis? I don't know; My wife's an artist, she picked it, please go ask her. ^_~

I'm just the grunt building the beast for her.

Anubis will be used for solid object modelling and rapid prototyping, so we needed a dual-CPU motherboard and tower case that will fit it. It essentially needs as much processing power as we can throw at it. Since my wife is both an artist and a scary FPS gamer - she shames me all the time in Quake T-T - we also planned on using video cards in SLi.

Two CPUs, an eATX motherboard, two video adapters, and an SAS hard drive would have been much too loud with pure air cooling. Liquid-cooling wasn't so much a possible choice as much as it was a need.

My background is that of an engineer - specifically electrical and computer science. I can also wield a Dremel.

Apart from simply working, I also wanted Anubis to look good. That meant sleeving exposed wires with non-conductive reflective plastics, using straight lines whenever possible ( flow rate be damned ^_^; ), hiding wiring, and internal lighting. A note about the lighting: There's a three-way switch in the back of the case that lets us select between UV lighting, visible blue lighting, or no lights. Power to the lights are controlled remotely via a hand-held fob. Think of a wireless keyless entry system on a vehicle - that's exactly how it works.

Components installed thus far:

Case: Thermaltake Armor

Motherboard: SuperMicro H8DAi-2 (Double Quad-core Opteron capable)

Radiators: HardwareLabs

1 - Black Ice GT Stealth X-Flow 120mm (Blue)

1 - Black Ice GT Stealth 120mm (Blue)

1 - Black Ice Micro 80mm (Blue)

Reservoirs: Danger Den

2 - Acrylic Clear Reservoir

Pumps: Laing

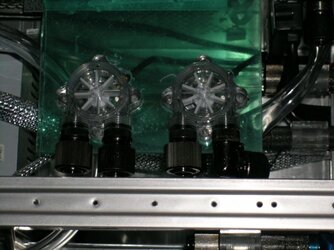

2 - DDC 3.2 18W pumps

Pump tops: Radiical

2 - Turbo Head Series 3 Pump Housing For Laing DDC-3.2 12 Volt Pumps

Fan controllers:

1 - Zalman ZM-MFC2 with power usage monitoring

1 - Logisys Silver 3.5 Inch LCD Thermal Controller (FP206SL)

Fans:

1 - Everflow 120mm PWM Fan (R121225BU)

2400 R.P.M. Maximum @ 110 CFM (39.5 dBA)

1500 R.P.M. @ 66 CFM (30.5 dBA)

1 - Evercool AL12025

2000 R.P.M. Maximum @ 79.1 CFM (30 dBA)

1 - Evercool 80mm AL8025B

2500 R.P.M. Maximum @ 32.4 CFM (25 dBA)

Fillport: Koolance Coolant Fill Port

Flow meters: Koolance

2 - Coolant Flow Meter (INS-FM16)

2 - Flow Meter Power Adapter (ADT-FM002K)

T-connectors: Danger Den Acrylic G1/4 T-connectors

Plugs: Bitspower

4 - G 1/4 acrylic ("crystal") plugs

Thermal sensors: Cooler Master

4 - Thermal Sensor Cable

Compression fittings: Koolance G1/4 1/2" I.D. 5/8" O.D.

Drainport:

1 - Dental Equipment Parts Quick Disconnect Coupler with Shut-Off (Part #09-0044-00)

1 - Dental Equipment Parts Quick Disconnect Insert without Shut-Off (Part #09-0032-00)

Syringe: Danger Den Filling Syringe

Wire guides: Zip tie hold downs - The Home Depot is your friend

SAS Cables: OKGear 10" SATA-II Cable - Clear Silver (GC10ATASM)

Combo SATA & Power Cable: OKGear 14" Silver SATA Cable and Power Combo Plug (OK105 Silver)

Slot protectors: Lamptron UV Blue Slot Protector for RAM, PCI, & PCIe slots

Light remote: Logisys 12V 15A/6A Relay W/ Remote Control (RM02 or RM01)

Power converter: AsiaEngineer DC OR AC to DC 5V Converter

Lights:

2 - Logisys 12" Day and Night Blue/UV Interchangable CCFL Kit (CLK12ST2)

4 - Danger Den 5mm UV LED tailed

Worklog notes:

- Danger Den fillports are too tall to fit underneath the Armor's bonnet

- The Koolance flow meters are designed to work with motherboard/fan controller RPM monitoring inputs. 1 liter per minute of flow is equal to ~1,000 R.P.M.

- Two of the Danger Den UV LEDs burned out. One died within ten minutes of connection, and the other died after about a week. Total usage on the second one that died was less than ten continuous hours...

- Thermaltake T-Type Water Temperature Indicator (CL-W0033) while able to accept 1/2" I.D. tubing, are much too restrictive internally, ridiculously restrictive in fact.

- Koolance G 1/4 fluid thermistors have much too high an internal resistance to correctly be read by standard fan controllers.

- January 9 2008 update: Added pump and pump top information

- March 16, 2008 update: Added motherboard, SAS/SATA cable, and slot protector information

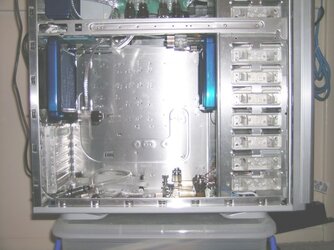

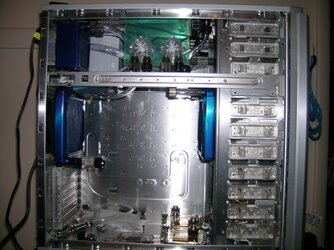

Two of the radiators have been installed, both in a "pull" fan configuration. Four UV LEDs are lighting up the two reservoirs. Eventually, there will be an exhaust duct connecting the 120mm radiator on the right to the front of the case. The blue LED fan will also be replaced with a PWM fan that can pump considerably more air. Wires are everywhere - it looks much too messy. I plan on drilling a hole in the bonnet atop the case to install a fillport. An automatically-sealing drainport will be installed at the bottom left of the case.

Here's an action shot with the lights powered on. The CCFLs have been hidden behind support bars so that they only illuminate the case, and don't cause blindness. Double-sided velcro holds the upper lamp in place, and simple tension secures the lower one.

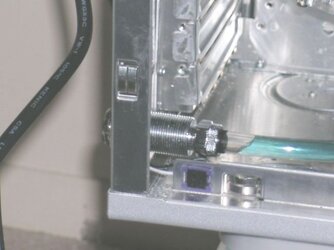

Here's a close up of where the flow meters will be installed.

I plan on cutting openings shaped like the flow meters' outlines in a polycarbonate ("Lexan") sheet and suspending the sheet, with the flow meters inside, from the top of the case.

This is our inexhaustible, fully redundant (two cheek pouches!), 1.2 kilowatt power supply, Lina. She's walking away, unhappily, because we decided that we're not going to use her to power Anubis.

Instead, I plan on using a single-rail 1KW PSU from PC Power & Cooling. The power supply currently inside the case is an old 200W clunker. It provides power solely for testing the lights.

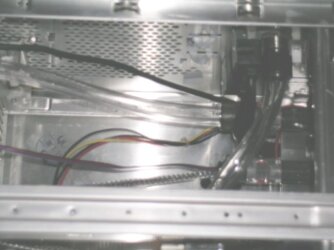

Wire management has been completed and all but one fan wire, one PSU wire bundle, and the power monitoring cable have been sleeved. The power monitoring cable has been moved to the top of the case - look at the cord with the yellow tab at the top left of the image. The exhaust duct has been installed on the radiator on the right side, and the flow meters have been connected to their controllers.

The flow meters are currently sitting on the bottom of the case. They've been configured to strobe based upon the flow rate of the fluid; greater flow means more frequent strobing. Acrylic T-connectors and temperature monitoring thermistors have been connected inline with the radiators and reservoirs. A couple of tubes have also been installed. The tubing is for sacrificial purposes only, it's Clear Flex brand from the local Microcenter and it'll be used for measuring how much real tubing is needed. I plan on using Tygon brand tubing in the finished system. Some cautioning words of note: the Clear Flex tubing kinks much too easily.

Here's the same view with the side panel removed. The black cable at the top is the power monitoring cable.

Here's a close-up of the fill-line attached to the fillport and also the tube leading from the topmost radiator to the topmost reservoir.

Did I mention that the system will use two interconnected loops for circulation and drainage? Well, it will, and it was a pain in the toosh to calculate the flow-rates and associated heat dissipation values. With the pumps and the fans in the system running at top speed, the system will be able to exhaust up to 748 watts of heat each minute.

Here's a picture of the front of the case, with the bonnet opened. All of the electrical connections inside the bonnet have been preserved and more importantly still work. The stacked reservoirs are gorgeous. Although, I anticipate that bleeding air from them is going to be a pain in the toosh.

Last edited:

to the forums btw. you'll find it a most helpful resource

to the forums btw. you'll find it a most helpful resource