- Joined

- Jul 16, 2007

- Location

- the present

The Fedex dude just dropped off a lot of loot...

Thermochill PA120.3 with 1/2" Plastic Barbs

Swiftech MCP655™ 12 VDC Pump

D-Tek FuZion Accelerator Nozzle Kit

Dtek FuZion Intel 775 Pro-Mount set

Swiftech MCW60-R VGA cooler

Swiftech MCW30 Chipset cooler

3 x YATE LOON 120x120x20mm Case Fan - D12SM-12C Medium Speed

15' ClearFLEX 60 Tubing 1/2" ID / 3/4" OD

Swiftech MCRES-Micro

D-TEK FuZion Universal CPU Waterblock - 1/2"

Swiftech MC8800 SMC Cooling Kit

15 x Stainless Steel Worm-Drive Hose Clamp (Wide Band w/Liner)

Petra'sTech "PT_Nuke" Concentrated Biocide (10mL)

Danger Den Acetal T-Fitting

Danger Den Acetal FillPort

EK High-Flow Fitting (G EK-G38-12 3/8" Thread, 1/2" OD)

I've got my work cut out for me. This is my first attempt at h2o. Any last minute advice or tips for me?

All I'm doing is following this guide. I hope it's not too out of date.

How important is the McMaster-Carr filter? I don't have one.

On my way to the store to pick up a few gallons of distilled water and vinegar for cleaning. wooT

2008-02-15

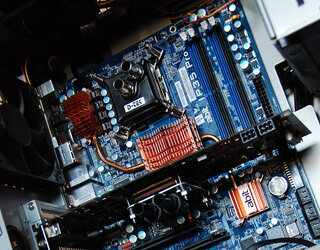

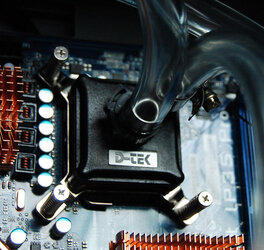

Today, I finally busted out the water blocks after flushing the radiator out last week. I mounted the Fuzion & used the quad nozzle. Also pulled off the stock cooler on my 8800 Ultra and cleaned it up.

2008-02-17

Today, I made my brackets to mount the radiator off the back of my case. Not as pretty as the build that inspired me (lasse.j5 at XS), but same idea. Also cut holes in the case for rad tubing.

2008-02-18

I wanted to cut some tubing so, today, I dry mounted everything except the reservoir. I damaged an o-ring and need to get another before I can mount the res. Also, I'm still trying to decide where to actually put the res. Also thinking about getting the EK res and mounting it the way lasse.j5 did, and even use the fill port hole in the top of the case.

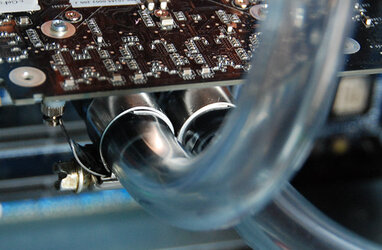

Using 3/4" OD tubing with the Fuzion means there is little to no room for hose clamps. It was pretty tight where the tubing meets. First, I put a black, plastic clamp on the in-flow. Then I painstakingly worked a metal worm-drive on the out-flow right up to the plastic clamp.

the VGA clamps

And here's where I stopped. The unconnected tubes are stuffed into the 5.25" bay in the upper right hand side since the res isn't included yet.

Thermochill PA120.3 with 1/2" Plastic Barbs

Swiftech MCP655™ 12 VDC Pump

D-Tek FuZion Accelerator Nozzle Kit

Dtek FuZion Intel 775 Pro-Mount set

Swiftech MCW60-R VGA cooler

Swiftech MCW30 Chipset cooler

3 x YATE LOON 120x120x20mm Case Fan - D12SM-12C Medium Speed

15' ClearFLEX 60 Tubing 1/2" ID / 3/4" OD

Swiftech MCRES-Micro

D-TEK FuZion Universal CPU Waterblock - 1/2"

Swiftech MC8800 SMC Cooling Kit

15 x Stainless Steel Worm-Drive Hose Clamp (Wide Band w/Liner)

Petra'sTech "PT_Nuke" Concentrated Biocide (10mL)

Danger Den Acetal T-Fitting

Danger Den Acetal FillPort

EK High-Flow Fitting (G EK-G38-12 3/8" Thread, 1/2" OD)

I've got my work cut out for me. This is my first attempt at h2o. Any last minute advice or tips for me?

All I'm doing is following this guide. I hope it's not too out of date.

How important is the McMaster-Carr filter? I don't have one.

On my way to the store to pick up a few gallons of distilled water and vinegar for cleaning. wooT

2008-02-15

Today, I finally busted out the water blocks after flushing the radiator out last week. I mounted the Fuzion & used the quad nozzle. Also pulled off the stock cooler on my 8800 Ultra and cleaned it up.

2008-02-17

Today, I made my brackets to mount the radiator off the back of my case. Not as pretty as the build that inspired me (lasse.j5 at XS), but same idea. Also cut holes in the case for rad tubing.

2008-02-18

I wanted to cut some tubing so, today, I dry mounted everything except the reservoir. I damaged an o-ring and need to get another before I can mount the res. Also, I'm still trying to decide where to actually put the res. Also thinking about getting the EK res and mounting it the way lasse.j5 did, and even use the fill port hole in the top of the case.

Using 3/4" OD tubing with the Fuzion means there is little to no room for hose clamps. It was pretty tight where the tubing meets. First, I put a black, plastic clamp on the in-flow. Then I painstakingly worked a metal worm-drive on the out-flow right up to the plastic clamp.

the VGA clamps

And here's where I stopped. The unconnected tubes are stuffed into the 5.25" bay in the upper right hand side since the res isn't included yet.

Last edited: