- Joined

- Jan 19, 2008

- Location

- Folding the PWN, Salem Oregon

starting my water loop.

I read the sticky on how to post so in order:

I want to water cool because I'm going for a quieter machine and the performance boost.

Budget is pretty small as I'm still in high school and don't have time for a job and my parents don't wanna give me any money but i can probably get around 120-150$

I have a shop full of tools at my disposal and a pc club, home depot, and scrap yard not far away.

The case is: http://www.pcclub.com/product_details.cfm?itemno=A1313319

Parts are listed in my sig, the only thing i want to cool for now is the cpu.

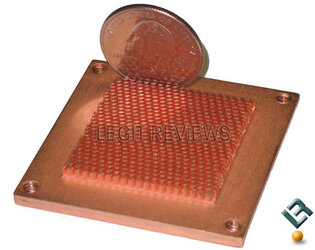

I was planning on making a custom copper block as it wont be much trouble and id like to give building one a try. this is the radiator i was looking at: http://www.xoxide.com/swiftech-mcr120-quiet-radiator.html

Im gonna head down to the aquatics pet shop to see what they had for pumps. the res would be a simple t line and im gonna check the pc shops around for tubing.

I read the sticky on how to post so in order:

I want to water cool because I'm going for a quieter machine and the performance boost.

Budget is pretty small as I'm still in high school and don't have time for a job and my parents don't wanna give me any money but i can probably get around 120-150$

I have a shop full of tools at my disposal and a pc club, home depot, and scrap yard not far away.

The case is: http://www.pcclub.com/product_details.cfm?itemno=A1313319

Parts are listed in my sig, the only thing i want to cool for now is the cpu.

I was planning on making a custom copper block as it wont be much trouble and id like to give building one a try. this is the radiator i was looking at: http://www.xoxide.com/swiftech-mcr120-quiet-radiator.html

Im gonna head down to the aquatics pet shop to see what they had for pumps. the res would be a simple t line and im gonna check the pc shops around for tubing.

Last edited: