- Joined

- Mar 8, 2002

- Location

- Rio de Janeiro - Brazil

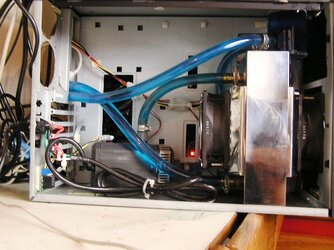

Hi friends, my new radiator is coming, so that i can make a dual loop setup to cool :

CPU - Pentium 4 3.0C with a cascade block(already cooled)

Nortbridge with a chipset block mcw20P(not yet)

Radeon 9800 pro already cooled with a 80 w TEC block MCW 50T

I have tried to cool with an EHEIM 1250 pump and a radiator(F2 with 2 delta fan 120x38), but the temp is pretty high

So i have bought :

Danner 500 gph pump

Caprice HC double shoudred and 2 fans

MCW 20P chipset block

2 Y conections

T reservoir

DD clear reservoir

My intention is cool the cpu with the danner and the caprice rad(the CPU draw up to 130 W when overclocked), and the other parts(chipset and the tec block) with the EHEIM 1250 and the F2 radiator ,like pump - MCW 20P - TEC block - T reservoir

Anybody has opinions with this setup, like running the blocks parallel, change pumps order, etc.

I do have pics of everything, just LMK.

Regards

CPU - Pentium 4 3.0C with a cascade block(already cooled)

Nortbridge with a chipset block mcw20P(not yet)

Radeon 9800 pro already cooled with a 80 w TEC block MCW 50T

I have tried to cool with an EHEIM 1250 pump and a radiator(F2 with 2 delta fan 120x38), but the temp is pretty high

So i have bought :

Danner 500 gph pump

Caprice HC double shoudred and 2 fans

MCW 20P chipset block

2 Y conections

T reservoir

DD clear reservoir

My intention is cool the cpu with the danner and the caprice rad(the CPU draw up to 130 W when overclocked), and the other parts(chipset and the tec block) with the EHEIM 1250 and the F2 radiator ,like pump - MCW 20P - TEC block - T reservoir

Anybody has opinions with this setup, like running the blocks parallel, change pumps order, etc.

I do have pics of everything, just LMK.

Regards