- Joined

- Nov 5, 2004

- Location

- Southern California

I thought I would write this after I asked a question regarding painting a faceplate to match my aluminum case and the answers were things like I used aluminum foil and use what you have been using.

To test all the paints I bought 15 identical generic face plates and lightly sanded them with 1500 then 2000 grit wet/dry sandpaper.

My two concerns were being first being able to match color and second durability.

How I gauged color and durability were as follows.

Color matching: I used the source that I wanted matched to the paints in question.

Durability: I basically created a standard torture which involved flexing the face plates, attaching them to a string and letting them swing in the corner of a table and dropping a handful of gravel on them, yes I know not the most scientific but I wanted to do the absolute worst case scenario to see how well they held up.

The 3 options for painting are enamel’s, acrylics and lacquers

Enamel: of the 3 brands that I was able to find: (which were spray paint)

1.) Dutch Boy Spray-Enamel (aluminum)

2.) Ace Hardware - Enamel (aluminum)

3.) Krylon Dull Aluminum #1403

Both 1 and 2 are not really suited to plastics, allowing 8 hours between coats and lightly dusting from around 18” to 24” away (any closer tended to overcoat and pool) both needed light sanding due to speckling and light waves between coats.

On the other hand took to plastic very nicely however the finish/color could be hardly be considered aluminum at best maybe a primer gray, no metallic qualities what so ever.

All three were very durable one might even say bullet proof.

Another inherent problem with all 3 enamel’s I tried was they all discolored when touched blackened to be more specific.

Acrylics: I was only able to find 2: (both came in ½ oz. bottles, not spray cans)

1.) Model Master – 4677 (aluminum)

2.) Model Master – 4678 (silver)

I enlisted the aid if a friend who is an airbrush artist as I was not going to hand paint them and couldn’t justify buying an airbrush setup just for an experiment.

With her expert hand both went on smoothly in two coats without needing to be sanded.

Both had blindingly glossy finishes which in both of our opinions stood out in stark contrast to the satin finish if the case.

The color on the aluminum looked more like polished silver very bright, and the color on the silver looked one or two shades light of chrome and again very bright not even close to the satin finish of the Lian-Li case I’m trying to match.

Durability: Not very, on the flex test small hair line fractures appeared in the finish. The surface was badly marred and pitted in the next tests as well.

Lacquers: we found and tested 5. Out of those only 2 merit mention.

1.) Pactra - RC262, Indy Silver 3 Oz. Spray Can

2.) Model Master – 1451, Aluminum Plate 3 Oz. Spray Can

These are both very different types of lacquers with unique properties.

Paint 1 went on like a breeze spraying from 12” to 20” away, it almost looks like spray glitter going on, the particulates of metal flaking are quite appetent.

It dries quickly w/ a fine metallic flake surface.

Durability: very durable, was completely unscathed by my abuse.

Paint 2 this is a buff-able lacquer and as such goes on like a spray powder which allows you to get different finishes. The down side to this is it requires a clear lacquer finish coat to seal it.

On my test plate I was able to match my color perfectly with a little light buffing with a piece of muslin, once to clear coat went on the color shifted slightly but not enough to dissuade my wanting to use it, however when I sprayed my Audigy face plate I ran in to a big snag. Its was easy to buff the flat face plate but the Audigy’s face plate is got all sorts of angles and contours which made it imposable to give it a uniform finish.

I ended up striping the paint off with lighter fluid and repainting it leaving the surface un-buffed.

Durability: paint two is durable only getting dinged up slightly with the gravel.

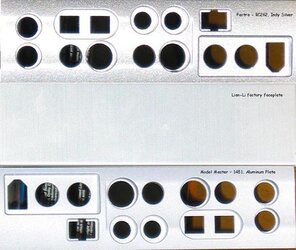

As I favor these last two paints I took pictures to illustrate their appearances.

I noticed that what my camera saw and what my eyes see are extremely different, both paints lightened a shade or two with the flash.

With the camera the Pactra - RC262, Indy Silver metal flaking gave the appearance of a course surface I would go so far to say pitted, but with the naked eye looks a little sparkly but in my opinion matches best with the finish of the case.

The Model Master – 1451, Aluminum Plate with the camera looks like a nearly perfect match, to the human eye looks much duller I wont go so far as to say gray but more on that side of the fence.

In conclusion for matching aluminum I strongly recommend lacquer paints.

I’m not a professional painter so I must confess ease if use did factor slightly into it but only slightly.

The bottom line was getting an aluminum paint that didn’t stand out like a sore thumb and wouldn’t discolor or get dinged up easily.

To me that puts both of the lacquers mentioned at the top of the charts, recommending them in the order listed

To test all the paints I bought 15 identical generic face plates and lightly sanded them with 1500 then 2000 grit wet/dry sandpaper.

My two concerns were being first being able to match color and second durability.

How I gauged color and durability were as follows.

Color matching: I used the source that I wanted matched to the paints in question.

Durability: I basically created a standard torture which involved flexing the face plates, attaching them to a string and letting them swing in the corner of a table and dropping a handful of gravel on them, yes I know not the most scientific but I wanted to do the absolute worst case scenario to see how well they held up.

The 3 options for painting are enamel’s, acrylics and lacquers

Enamel: of the 3 brands that I was able to find: (which were spray paint)

1.) Dutch Boy Spray-Enamel (aluminum)

2.) Ace Hardware - Enamel (aluminum)

3.) Krylon Dull Aluminum #1403

Both 1 and 2 are not really suited to plastics, allowing 8 hours between coats and lightly dusting from around 18” to 24” away (any closer tended to overcoat and pool) both needed light sanding due to speckling and light waves between coats.

On the other hand took to plastic very nicely however the finish/color could be hardly be considered aluminum at best maybe a primer gray, no metallic qualities what so ever.

All three were very durable one might even say bullet proof.

Another inherent problem with all 3 enamel’s I tried was they all discolored when touched blackened to be more specific.

Acrylics: I was only able to find 2: (both came in ½ oz. bottles, not spray cans)

1.) Model Master – 4677 (aluminum)

2.) Model Master – 4678 (silver)

I enlisted the aid if a friend who is an airbrush artist as I was not going to hand paint them and couldn’t justify buying an airbrush setup just for an experiment.

With her expert hand both went on smoothly in two coats without needing to be sanded.

Both had blindingly glossy finishes which in both of our opinions stood out in stark contrast to the satin finish if the case.

The color on the aluminum looked more like polished silver very bright, and the color on the silver looked one or two shades light of chrome and again very bright not even close to the satin finish of the Lian-Li case I’m trying to match.

Durability: Not very, on the flex test small hair line fractures appeared in the finish. The surface was badly marred and pitted in the next tests as well.

Lacquers: we found and tested 5. Out of those only 2 merit mention.

1.) Pactra - RC262, Indy Silver 3 Oz. Spray Can

2.) Model Master – 1451, Aluminum Plate 3 Oz. Spray Can

These are both very different types of lacquers with unique properties.

Paint 1 went on like a breeze spraying from 12” to 20” away, it almost looks like spray glitter going on, the particulates of metal flaking are quite appetent.

It dries quickly w/ a fine metallic flake surface.

Durability: very durable, was completely unscathed by my abuse.

Paint 2 this is a buff-able lacquer and as such goes on like a spray powder which allows you to get different finishes. The down side to this is it requires a clear lacquer finish coat to seal it.

On my test plate I was able to match my color perfectly with a little light buffing with a piece of muslin, once to clear coat went on the color shifted slightly but not enough to dissuade my wanting to use it, however when I sprayed my Audigy face plate I ran in to a big snag. Its was easy to buff the flat face plate but the Audigy’s face plate is got all sorts of angles and contours which made it imposable to give it a uniform finish.

I ended up striping the paint off with lighter fluid and repainting it leaving the surface un-buffed.

Durability: paint two is durable only getting dinged up slightly with the gravel.

As I favor these last two paints I took pictures to illustrate their appearances.

I noticed that what my camera saw and what my eyes see are extremely different, both paints lightened a shade or two with the flash.

With the camera the Pactra - RC262, Indy Silver metal flaking gave the appearance of a course surface I would go so far to say pitted, but with the naked eye looks a little sparkly but in my opinion matches best with the finish of the case.

The Model Master – 1451, Aluminum Plate with the camera looks like a nearly perfect match, to the human eye looks much duller I wont go so far as to say gray but more on that side of the fence.

In conclusion for matching aluminum I strongly recommend lacquer paints.

I’m not a professional painter so I must confess ease if use did factor slightly into it but only slightly.

The bottom line was getting an aluminum paint that didn’t stand out like a sore thumb and wouldn’t discolor or get dinged up easily.

To me that puts both of the lacquers mentioned at the top of the charts, recommending them in the order listed

Attachments

Last edited: