- Thread Starter

- #21

I officially give up on these clamps. They keep leaking and it is getting annoying. Gonna try with zip tie tomorrow.

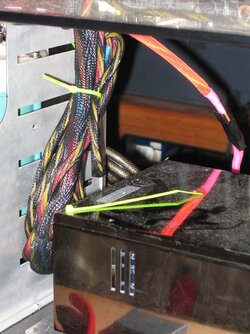

these are some pics. Let me know if you guys wanna see anything else. Nothing here in particular. The cables are as clean as it gets I think, minus some that I have not hidden them. Any recommendation will do. Enjoy

these are some pics. Let me know if you guys wanna see anything else. Nothing here in particular. The cables are as clean as it gets I think, minus some that I have not hidden them. Any recommendation will do. Enjoy

some sanding (and widening) of the blow hole is in order but other than that its sweet

some sanding (and widening) of the blow hole is in order but other than that its sweet