- Joined

- Dec 7, 2003

- Thread Starter

- #121

DIY Station #30

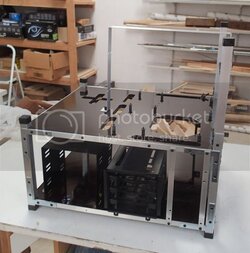

So it has been a while, but recently I got request for building a new DIY Station. This would be Station #30, what with my VLC (Very Low Cost) Stations, I’ve now built over 40!

This build request was for a fairly classic station with a couple of tweaks.

Going for the upgraded paint job.

Some custom watercooling pass thru cutouts.

Layout to include 2 power supplies and a radiator built into the lower deck.

First step was to start assembling all the components. Here were most of the raw materials for this build.

Next we settled on the layout of the cutouts. The client wanted a special cross shaped cutout for passing thru watercooling tubing.

(The finished panel on the left is my personal station, which I put in the picture for comparison and scale).

And proceeded to mill out top panel:

For milling out the passthrus and the under-cpu fan mount, I use a router with a ⅞” flush bit and a template bushing.

For all my traditional pass thrus and the cpu socket, I keep on hand some template jigs that mount to the motherboard socket holes, so that I can reproduce these slots quickly and repeatedly. For the custom cross shape, I used a straight edge clamp to guide the router.

Something like what I was doing in this pic:

So it has been a while, but recently I got request for building a new DIY Station. This would be Station #30, what with my VLC (Very Low Cost) Stations, I’ve now built over 40!

This build request was for a fairly classic station with a couple of tweaks.

Going for the upgraded paint job.

Some custom watercooling pass thru cutouts.

Layout to include 2 power supplies and a radiator built into the lower deck.

First step was to start assembling all the components. Here were most of the raw materials for this build.

Next we settled on the layout of the cutouts. The client wanted a special cross shaped cutout for passing thru watercooling tubing.

(The finished panel on the left is my personal station, which I put in the picture for comparison and scale).

And proceeded to mill out top panel:

For milling out the passthrus and the under-cpu fan mount, I use a router with a ⅞” flush bit and a template bushing.

For all my traditional pass thrus and the cpu socket, I keep on hand some template jigs that mount to the motherboard socket holes, so that I can reproduce these slots quickly and repeatedly. For the custom cross shape, I used a straight edge clamp to guide the router.

Something like what I was doing in this pic: