- Joined

- Jul 21, 2002

- Location

- Branford, CT USA

"Pumpout" low viscosity pastes - (repeat the mantra (quote below) with the Lite Beer Commercial of the 80's in your mind)

"All Fillers - No particles"

A result of this formula is something called pump-out occuring under the very conditions which are at the crux of our discussion. That formula: Heat + Pressure + Time = failure. Of course that xconclusion is forgone given the last value T but we don't want it to occur months after the paste has been applied.

While PC-enthusiats tend to change their CPU's every hour on the hour we are easily taken by pastes which set rapidly giving great temps but deteriorate almost as rapdily. We are immune to such problems simply because by the time the paste would begin to detrerioate we've already changed it out installing the newest core revision.

However we need to think about what makes a great thermal paste. As counterintuitive as it might seem Temperature is not the only attribute which determines success. Of course it's an intregal part of the equation. However; for the company running servers with millions invested in those files, experiencing an overall 5C drop in temps, while sacrificing 18-months of additional covereage, lower temps mean little compared to TIM lifespan. They need long-term stability, consistancy, longevity, and decenbt temps. And for the average PC user who applies a Bill-A-Goop type formula for instant gratification and then a year later wonder why their experiencing random re-booting, BSODs and buggy programs etc. They may suffer most because it never presents itself in a catastrophic failure, but months of frustration trouble shooting what are hardware issues misconstrued as software system errors.

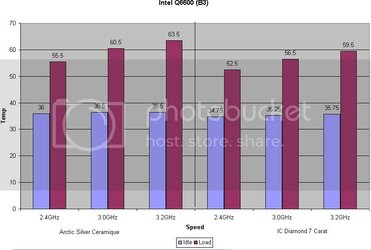

That's the worst case scenario of a "Pyromaniac Ghost in the Machine." What they need is a stable long lasting product. I'm running several new tests for my Thermal Paste Addendum which includes Noctua and IC-Diamond and some new tests. I've just finished testing Tuniq TX-2 under high-heat, high-pressure between the Q6600 and Swiftech Apogee GTX.

EDIT: I almost got confused as to wich paste I applied hehe. But from the next photos I have to get on my PC you'll see the difference betwen IC-Diamond and other pastes. It just doesn't "break down" as easily and the spread pattern look healthy. I am up early today whoo

Below is the paste after the fact, is this pump-out;

"All Fillers - No particles"

A result of this formula is something called pump-out occuring under the very conditions which are at the crux of our discussion. That formula: Heat + Pressure + Time = failure. Of course that xconclusion is forgone given the last value T but we don't want it to occur months after the paste has been applied.

While PC-enthusiats tend to change their CPU's every hour on the hour we are easily taken by pastes which set rapidly giving great temps but deteriorate almost as rapdily. We are immune to such problems simply because by the time the paste would begin to detrerioate we've already changed it out installing the newest core revision.

However we need to think about what makes a great thermal paste. As counterintuitive as it might seem Temperature is not the only attribute which determines success. Of course it's an intregal part of the equation. However; for the company running servers with millions invested in those files, experiencing an overall 5C drop in temps, while sacrificing 18-months of additional covereage, lower temps mean little compared to TIM lifespan. They need long-term stability, consistancy, longevity, and decenbt temps. And for the average PC user who applies a Bill-A-Goop type formula for instant gratification and then a year later wonder why their experiencing random re-booting, BSODs and buggy programs etc. They may suffer most because it never presents itself in a catastrophic failure, but months of frustration trouble shooting what are hardware issues misconstrued as software system errors.

That's the worst case scenario of a "Pyromaniac Ghost in the Machine." What they need is a stable long lasting product. I'm running several new tests for my Thermal Paste Addendum which includes Noctua and IC-Diamond and some new tests. I've just finished testing Tuniq TX-2 under high-heat, high-pressure between the Q6600 and Swiftech Apogee GTX.

EDIT: I almost got confused as to wich paste I applied hehe. But from the next photos I have to get on my PC you'll see the difference betwen IC-Diamond and other pastes. It just doesn't "break down" as easily and the spread pattern look healthy. I am up early today whoo

Below is the paste after the fact, is this pump-out;

Attachments

Last edited: