- Joined

- Dec 14, 2007

- Location

- California 805 ftw

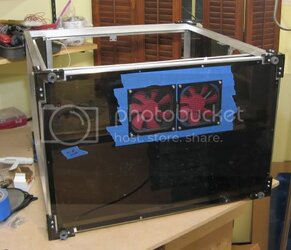

That grill looks really cool!!!!!!!!!!!!

That grill looks really cool!!!!!!!!!!!!

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

That grill looks really cool!!!!!!!!!!!!

That grill looks really cool!!!!!!!!!!!!