- Joined

- Apr 5, 2010

- Location

- New Hampshire, USA

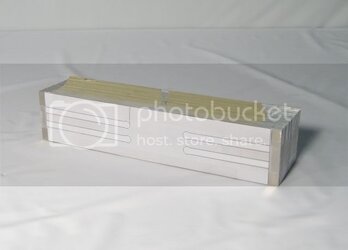

I was very fortunate to have been commissioned to build a large wooden tower case, to be used to hold a very large water cooled rig. Here's the design drawings:

The case is designed to contain an EATX motherboard, seven 5.25-inch drives and eight 3.5-inch hard drives. Two 120.4 radiators will eventually be mounted in the top chamber:

For wire routing/hiding, there's a "false back" between the mother board tray and the side panel:

The front fascia/panel is removable (although not on a hinge). Each horizontal "chamber" in the case is fed and exhausted by a 120mm fan.

Fresh air is supplied to the front fans via a bottom-fed, built-in air duct.

The first order of business was to fabricate the hard drive cages from 1/8-inch aluminum flat bar:

The drives are suspended in soft rubber grommets:

The cage/rails for the 5.25-inch optical drives were made from 1/8-inch aluminum sheet and 1/2-inch aluminum angle. The aluminum sheet was easily cut on the table saw (fitted with a carbide tipped saw blade). The strips were then stacked and a full-size template of a rail (drawn in Sketchup) was taped on.

The case is designed to contain an EATX motherboard, seven 5.25-inch drives and eight 3.5-inch hard drives. Two 120.4 radiators will eventually be mounted in the top chamber:

For wire routing/hiding, there's a "false back" between the mother board tray and the side panel:

The front fascia/panel is removable (although not on a hinge). Each horizontal "chamber" in the case is fed and exhausted by a 120mm fan.

Fresh air is supplied to the front fans via a bottom-fed, built-in air duct.

The first order of business was to fabricate the hard drive cages from 1/8-inch aluminum flat bar:

The drives are suspended in soft rubber grommets:

The cage/rails for the 5.25-inch optical drives were made from 1/8-inch aluminum sheet and 1/2-inch aluminum angle. The aluminum sheet was easily cut on the table saw (fitted with a carbide tipped saw blade). The strips were then stacked and a full-size template of a rail (drawn in Sketchup) was taped on.