- Joined

- Sep 21, 2010

Hi, welcome to 7Cubed

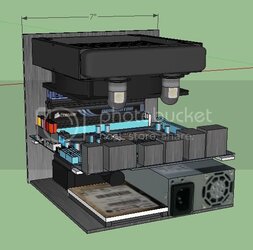

I recently got out of the planning stages and onto building and hardware.

First a brief rundown of my idea,

A perfect (well kinda, you'll see) 7" cube the houses a mini itx motherboard, all the standards and is water cooled. The material is 1/8" steel welded together.

Inspirations for this case are: Oliverw92 (and more specifically his MINIME case), Janik M. aka Xien16 and http://www.million-dollar-pc.com/sys...-janik/037.htm, and many others.

if you want to see about in some more detail the design challenges that faced this project see

http://forums.bit-tech.net/showthread.php?t=194611

Current state

Hardware

Hardware

Core i3 530

H55N-usb3 motherboard

Zotac GPU

Corsair 4gb ddr3 dominator at 1600mhz

Lite on slot load dvd burner

For some visuals

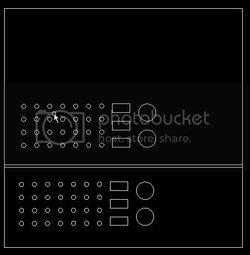

Sides which will be CNC plasma cam cut

Right

Holes are for cords and tubes that will run outside of case because of the 1/20" space between the sides and the motherboard.

Don't worry they will look purty

Okay enough with the conceptual time for some hardware

the base

an h55n

The PSU it's so cute. It's also an FSP270 flex atx

Installed with corsair dominator memory

and an i3 530 to top it all of, IT"S MY FIRST INTEL CPU AND IT"S SO SMALL

Checking to make sure everything's in order

Thanks for looking I'll have pics of the beginning stages up by tomorrow.

I recently got out of the planning stages and onto building and hardware.

First a brief rundown of my idea,

A perfect (well kinda, you'll see) 7" cube the houses a mini itx motherboard, all the standards and is water cooled. The material is 1/8" steel welded together.

Inspirations for this case are: Oliverw92 (and more specifically his MINIME case), Janik M. aka Xien16 and http://www.million-dollar-pc.com/sys...-janik/037.htm, and many others.

if you want to see about in some more detail the design challenges that faced this project see

http://forums.bit-tech.net/showthread.php?t=194611

Current state

Hardware

HardwareCore i3 530

H55N-usb3 motherboard

Zotac GPU

Corsair 4gb ddr3 dominator at 1600mhz

Lite on slot load dvd burner

For some visuals

Sides which will be CNC plasma cam cut

Right

Holes are for cords and tubes that will run outside of case because of the 1/20" space between the sides and the motherboard.

Don't worry they will look purty

Okay enough with the conceptual time for some hardware

the base

an h55n

The PSU it's so cute. It's also an FSP270 flex atx

Installed with corsair dominator memory

and an i3 530 to top it all of, IT"S MY FIRST INTEL CPU AND IT"S SO SMALL

Checking to make sure everything's in order

Thanks for looking I'll have pics of the beginning stages up by tomorrow.

Last edited:

, it's not too hard to fix though

, it's not too hard to fix though