-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Fan Controller for PWM Fans

- Thread starter Overclockers.com

- Start date

Can anyone please explain why most of 555-based PWM controllers use transistors but the one linked in the article in the OP doesn't?

See for example http://www.555-timer-circuits.com/motor-pwm.html

See for example http://www.555-timer-circuits.com/motor-pwm.html

Thank you. But what about those controllers with transistors that are intended for PC fans? The proponents are actually not that savvy?PC fans are not classical DC motors. They're actually synchronous AC motors with integrated inverters. Some of those inverters accept a logic level PWM signal for speed control.

- Joined

- Oct 30, 2009

PC fans are not classical DC motors. They're actually synchronous AC motors with integrated inverters. Some of those inverters accept a logic level PWM signal for speed control.

Thank you. This (with some explication by Wikipedia) finally explains our fans.

- Joined

- Mar 1, 2013

Some older PC type fans are designed to be PWMed just like an actual DC motor. Or voltage modulated with a buck converter. Nowadays, logic level PWM is the recommended way as it gives the best control.Thank you. But what about those controllers with transistors that are intended for PC fans? The proponents are actually not that savvy?

BTW, while standard PC fans with PWM are designed for about 25kHz noninverted, that's not the case for some fans designed for other applications like A/C indoor units. I have a 120mm Delta that was intended for a small Daikin mini split unit and not only is the PWM signal inverted, it works erratically at 25kHz PWM frequency. I don't have the indoor unit it is intended for but some experimentation with the 555 circuit gave pretty good control at about 1kHz. (In summary, if you have a fan that works erratically with the 555 controller, try lowering the frequency.)

Two more questions.

1. If a fan is going to operate at full speed, does it make sense to feed it with PWM signal at all?

2. Regardless of the above. If I'd like to disable the PWM signal, can I simply cut the 5V supply to the 555 PWM control circuit or is cutting off the PWM signal wire off using a switch the only option?

1. If a fan is going to operate at full speed, does it make sense to feed it with PWM signal at all?

2. Regardless of the above. If I'd like to disable the PWM signal, can I simply cut the 5V supply to the 555 PWM control circuit or is cutting off the PWM signal wire off using a switch the only option?

Last edited:

- Joined

- Dec 6, 2010

Two more questions.

1. If a fan is going to operate at full speed, does it make sense to feed it with PWM signal at all?

2. Regardless of the above. If I'd like to disable the PWM signal, can I simply cut the 5V supply to the 555 PWM control circuit or is cutting off the PWM signal wire off using a switch the only option?

If your not going to use the PWM signal, then you realy don't need the 555 circuit, you can leave the PWM line not connected and the fan will run full speed.

- Joined

- Feb 21, 2006

- Location

- Oklahoma City

PC fans are not classical DC motors. They're actually synchronous AC motors with integrated inverters. Some of those inverters accept a logic level PWM signal for speed control.

That still doesn't answer the question. The output of the transistor will be logic level, so long as the voltage input to the transistor is 5v (or whatever the logic voltage is at). I was curious about this as well. The circuit in the original link is rather odd and I've never seen one like it before. Usually the pot controls the RC timing circuit of the 555 and the output is sent through a transistor. This has the pot on the output. A very odd circuit.

This was a stupid question actually. 100% speed PWM signal is simply continuous ('a flatliner') so there's no difference between such state and e.g. the PWM cable cut out and PWM 555 module ripped out from the board.If your not going to use the PWM signal, then you realy don't need the 555 circuit, you can leave the PWM line not connected and the fan will run full speed.

In the light of this I guess the answer to the question #2 is: "cut the 5V supply to the 555 PWM control circuit".

Last edited:

Sorry to resurrect this but does anyone know how I can go about building a PWM fan controller that adjusts the duty cycle based off of a thermistor? There would need to be a way of adjusting. I would want it to be as basic as possible as long is it achieved the ability to what resistance meant the lowest PWM signal and what meant the highest and that the controller had some sort of linear increase in duty cycle as the temperature went up.

For example I would like the lowest duty cycle at 30C and the highest at 45C

If anyone could answer this it would be great. I have a Corsair Link Mini and had the original and neither have ever worked properly at all. The Mini will not function when you assign an external temperature probe to the fan. Only software based temps for things like CPU, VGA, HD, MOBO etc. As soon as you set it to run the fan curve off an external probe it just goes to stays at one setting even though the software shows the probes are working and reporting accurate temperatures.

Thanks guys

For example I would like the lowest duty cycle at 30C and the highest at 45C

If anyone could answer this it would be great. I have a Corsair Link Mini and had the original and neither have ever worked properly at all. The Mini will not function when you assign an external temperature probe to the fan. Only software based temps for things like CPU, VGA, HD, MOBO etc. As soon as you set it to run the fan curve off an external probe it just goes to stays at one setting even though the software shows the probes are working and reporting accurate temperatures.

Thanks guys

I've started piling up the components for this project. A question. Are any of the listed ceramic capacitors NOT replaceable by an electrolytic capacitor? I could get only those from my local el store.

Edit:

OK, I've just re-visited the article and nowhere it says they should actually be ceramic capacitors. I honestly have no idea where did I come up with that

Edit:

OK, I've just re-visited the article and nowhere it says they should actually be ceramic capacitors. I honestly have no idea where did I come up with that

Last edited:

Another question. PWM signal off, fan power on case is clear. The fan should go full speed. What about the opposite case? If I disconnect the power line from my fan, do I have to use a separate mechanism for disconnecting the power to the PWM signal generating circuit?

Another question. PWM signal off, fan power on case is clear. The fan should go full speed. What about the opposite case? If I disconnect the power line from my fan, do I have to use a separate mechanism for disconnecting the power to the PWM signal generating circuit?

Don't need to worry, its safe to have the PWM controller still at on state (powered), while the fan is totally off from it's power.

Of course this assumed that you're not using those rare and weird non standard industrial fans.

Thanks!Don't need to worry, its safe to have the PWM controller still at on state (powered), while the fan is totally off from it's power.

Of course this assumed that you're not using those rare and weird non standard industrial fans.

It's good to see that it's not the caseeveryone's got their pwm controllers up and running and I'm just the only one hanging out here

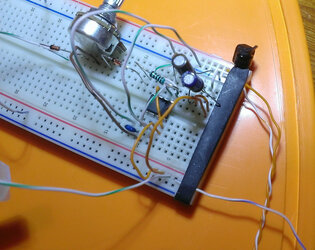

I got all my stuff together and I've put first circuits together recently, on a breadboard. Please mind that I use the project as my first elecronics introductory project.

The wiring diagram I've transfered to Fritzing is here:

http://www.overclockers.com/forums/...for-PWM-Fans?p=7845273&viewfull=1#post7845273

Take 1:

High pitch noise, only 10% RPM control authority. I scrapped the entire thing from the breadboard to start fresh.

Take 2 (with stock AMD fan and SilentiumPC Zephyr PWM):

a) [strikethrough]low volume high pitch noise in case of Zephyr[strikethrough] EDIT: No problems with Zephyr (the minor ticking noise is also present without the PWM signal applied)

b) weird behavior of stock AMD fan (loud pitching noise, very low RPM adj. range)

Could anyone help me here? What could be the problem? I have already re-checked the circuit branch after branch, to the best of my knowledge.

You can find a video, photos of the breadboard setup as well as a schematic of the breadboard layout along with a fritzing file that includes the breadboard layout that almost completely reflects the physical layout I've used.

Additional info:

a0. wires connected to the breadboard rails: orange: 12V, white with a blue line alongside: 5V, white with an orange line alongside: ground.

a1. Unlike the reference design from the article I've replaced one of the ceramic capacitors with an electrolytic one, solely due to availability problems.

a2. When I try to connect 5V supply voltage (at the 5V breadboard rail, at a point far to the right) to a fan instead of 12V the 555 PWM circuitstops working. It doesn't provide the control signal anymore.

a3. file module_pwm_555_fan_controller_overclockersdotcom02c_bb.png - the dashed lines at the 555 chip are due to bugs in Fritzing. The missing connection at the diodes has been established on my breadboard before the test I'm discussing here.

http://1drv.ms/2059Boh

a4. My meter doesn't feature frequency measurement so I've measured AC voltage at PWMline<->ground. The resulting range was 0.2 through 8.5V.

A teaser photo

Last edited:

I have tested the circuit with several additional PWM fans:

fan/note

Noctua NF-A14 / stops below 15 deg of pot. angle

Corsair 120mm CF12S25M12AP (from H60, H60i) / 95% RPM is the lowest achievable RPM

SilentiumPC Fortis 2 / ?

SilentiumPC Zephyr / 100% RPM at 3/4 pot. rotation

So I either made a mistake in the circuit or the circuit is no universally compatible with all PWM fans.

Note:

The article mentions the single 555 timer based PWM circuit is incapable of commanding a full 100% RPM of a connected fan. For every single fan I've tested so far there was no perceivable difference in RPM between the PWM circuit set to max and PWM disconnected.

fan/note

Noctua NF-A14 / stops below 15 deg of pot. angle

Corsair 120mm CF12S25M12AP (from H60, H60i) / 95% RPM is the lowest achievable RPM

SilentiumPC Fortis 2 / ?

SilentiumPC Zephyr / 100% RPM at 3/4 pot. rotation

So I either made a mistake in the circuit or the circuit is no universally compatible with all PWM fans.

Note:

The article mentions the single 555 timer based PWM circuit is incapable of commanding a full 100% RPM of a connected fan. For every single fan I've tested so far there was no perceivable difference in RPM between the PWM circuit set to max and PWM disconnected.

Last edited:

- Joined

- Apr 4, 2011

I have tested the circuit with several additional PWM fans:

fan/note

Noctua NF-A14 / stops below 15 deg of pot. angle

Corsair 120mm CF12S25M12AP (from H60, H60i) / 95% RPM is the lowest achievable RPM

SilentiumPC Fortis 2 / ?

SilentiumPC Zephyr / 100% RPM at 3/4 pot. rotation

So I either made a mistake in the circuit or the circuit is no universally compatible with all PWM fans.

Note:

The article mentions the single 555 timer based PWM circuit is incapable of commanding a full 100% RPM of a connected fan. For every single fan I've tested so far there was no perceivable difference in RPM between the PWM circuit set to max and PWM disconnected.

the NF-A14 should never stop spinning on any lowest pot position as the noctua stated themselves that the minimum RPM is 300 (+/- 20%)

you need to dig up infos on the "kilo post thread" to solved your issues.

I had no issue when dealing with any PC class fans, only few rare breeds of server fans giving me hard times... real hard, though

a1. Unlike the reference design from the article I've replaced one of the ceramic capacitors with an electrolytic one, solely due to availability problems.

Tell us more about this, does the replacement has "similar" capacitance ?

What is the "kilo post thread"? You mean the multi-page thread on PWM here on the forums? Could you recommend any keywords?the NF-A14 should never stop spinning on any lowest pot position as the noctua stated themselves that the minimum RPM is 300 (+/- 20%)

you need to dig up infos on the "kilo post thread" to solved your issues.

I had no issue when dealing with any PC class fans, only few rare breeds of server fans giving me hard times... real hard, though

The value is exact. 0.1uF if I remember correctly.Tell us more about this, does the replacement has "similar" capacitance ?

Similar threads

- Replies

- 0

- Views

- 695

- Replies

- 49

- Views

- 4K

- Replies

- 2

- Views

- 408