- Joined

- Nov 12, 2002

- Location

- Rootstown, OH

For those of you who haven't been following this tale, I'll catch you up quickly. As often good stories do, this one began with its main character set on a troubled path to glory: Vaseline was the leading man, and 8GHz was the goal. It went pretty well. 8.2GHz happened.

What can I say...

Following on this success, my love affair with Petroleum Jelly grew stronger. Until one fateful day, when I thought tape should work and be quicker to apply than eraser retention walls ...

But in this most recent issue of the vaseline tale, I once again have triumphed. I have refined my methods. Honed my craft. Tamed the jelly...

1. Prep board with eraser

Seal mobo mounting holes with eraser:

Seal socket mounting holes with eraser:

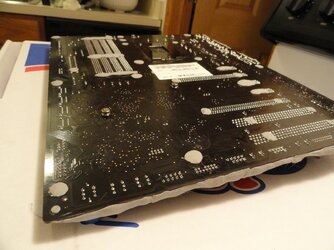

The back of the board:

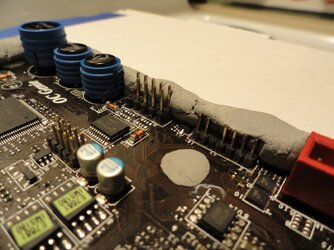

Seal PCIe mounting holes with eraser, heated vaseline flows like water, and will leak through these if not sealed:

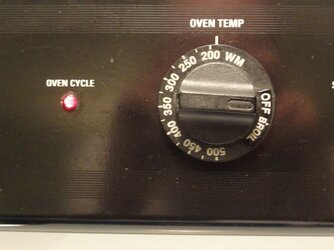

2. Set oven to just under 200F

3. Cook vaseline until melted (5-15 minutes)

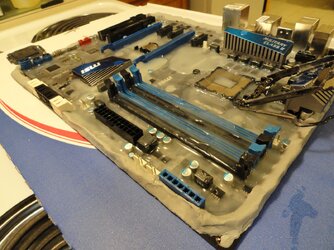

4. Apply liberally to area of interest with spoon. Ladle small amounts, allowing it to flow and spread around and under components. Small amounts ensures coverage without piles solidifying excessively in a given area. (this is excessive enough without literal piles)

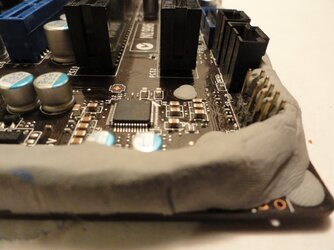

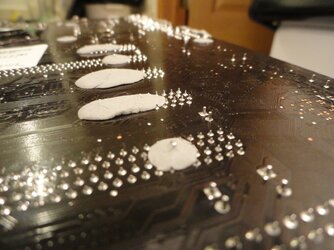

Melted vaseline will be clear:

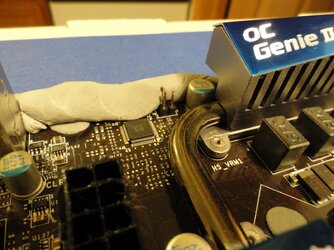

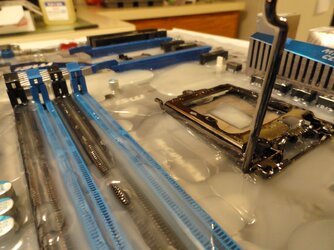

Socket:

Dimms:

So that's how vaseline insulation is done. This is a sandy bridge board, so its probably overkill - but its been rainy and humid here in Ohio, and that's likely to keep up through the spring. Using my blower, at temps of -20 to -80 I'll see a decent amount of condensation and melt. With insulation like this however, past experience has shown you can let everything melt, pick up the board to pour off the water, and just start running it again.

And its good practice for running AMD cold, the way cold is meant to be run.

What can I say...

Following on this success, my love affair with Petroleum Jelly grew stronger. Until one fateful day, when I thought tape should work and be quicker to apply than eraser retention walls ...

Oh god, the humanity... This day shall henceforth be remembered as V-day. The day Vaseline fought back.

The lower bathroom was the battlefield, and I might have left the hairdryer at its task unattended a touch too long. Too much heat. Too much liquid. Too much flowing Vaseline. Wave after wave. That bathroom has never seen anything like it... I'm considering drywalling over the door, writing it off as a total loss.

Tape retention walls suck.

But in this most recent issue of the vaseline tale, I once again have triumphed. I have refined my methods. Honed my craft. Tamed the jelly...

1. Prep board with eraser

Seal mobo mounting holes with eraser:

Seal socket mounting holes with eraser:

The back of the board:

Seal PCIe mounting holes with eraser, heated vaseline flows like water, and will leak through these if not sealed:

2. Set oven to just under 200F

3. Cook vaseline until melted (5-15 minutes)

4. Apply liberally to area of interest with spoon. Ladle small amounts, allowing it to flow and spread around and under components. Small amounts ensures coverage without piles solidifying excessively in a given area. (this is excessive enough without literal piles)

Melted vaseline will be clear:

Socket:

Dimms:

So that's how vaseline insulation is done. This is a sandy bridge board, so its probably overkill - but its been rainy and humid here in Ohio, and that's likely to keep up through the spring. Using my blower, at temps of -20 to -80 I'll see a decent amount of condensation and melt. With insulation like this however, past experience has shown you can let everything melt, pick up the board to pour off the water, and just start running it again.

And its good practice for running AMD cold, the way cold is meant to be run.