- Thread Starter

- #81

Lol!

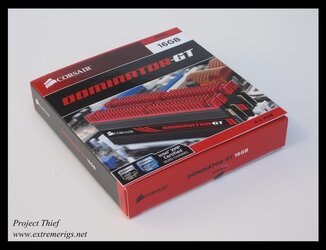

Another update:

Finished up the gtx 560 - here are some pics. Getting ready to start:

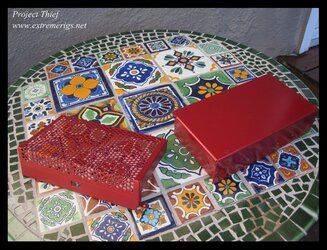

Chopping some heatshrink:

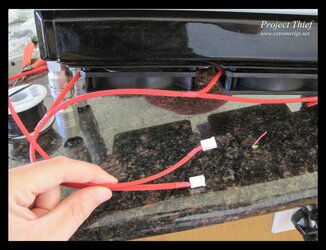

2 fans done - ignore the yellow wire - I'm not actually hooking up the tach wire to the 12V, I just reused the yellow wire for the 12V line:

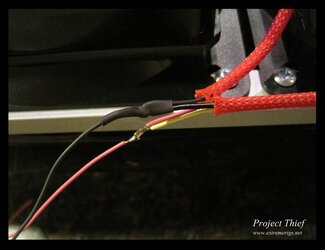

One thing I learned is that you don't have to join the wires all in the same place, in fact it's easier and less bulky if you join the 12V wires at one point, the 0V wires at another point and do the sleeving join at another point. This way you don't get one big lump. So don't do it like this is what I'm saying:

One side done - you can see the difference between the lumpy connection on the 3rd and 4th fan from the left, and the cleaner one on the 2nd/3rd:

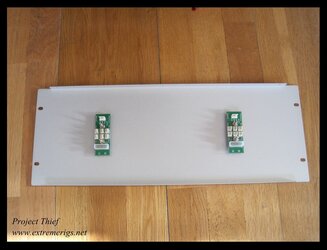

Now we have to move those fans on to the other (push) side of the radiator. So we have to add the 140mm adapters to the other side of the fan, and remove the adapters from the original side:

All done with that side, now let's go do the same thing again for the pull side:

Attaching the fans for the pull side:

Nearly done - but the last piece of sleeve pulled out of the heatshrink:

Replaced that section and all done:

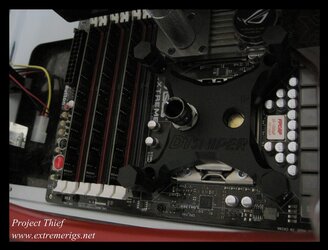

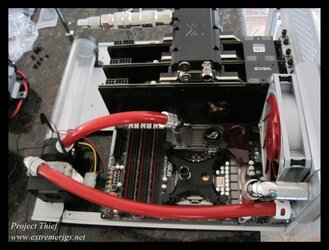

Installed - as you might be able to see, the section above with the low speed yates/HDDs still needs to be done:

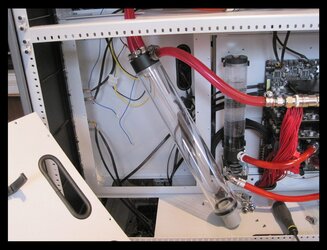

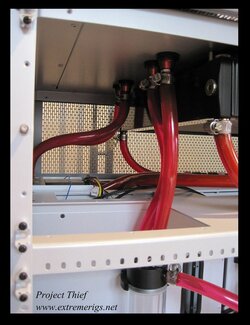

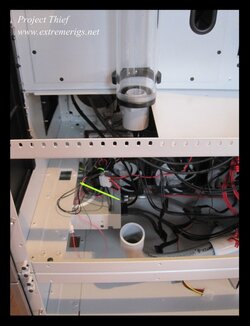

As you can see there's still a ton to do in the bottom compartment:

This side that's open right now will house the ex560 that's currently being used for testing waterblocks, and the gtx 360 that I'm going to go wire up and sleeve right now

I have some ideas for lighting too that I'm going to test out also

Another update:

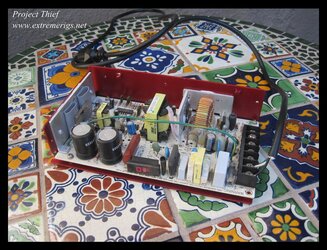

Finished up the gtx 560 - here are some pics. Getting ready to start:

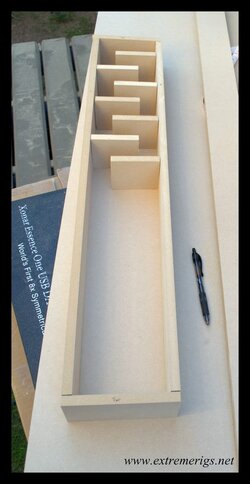

Chopping some heatshrink:

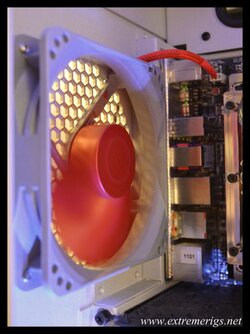

2 fans done - ignore the yellow wire - I'm not actually hooking up the tach wire to the 12V, I just reused the yellow wire for the 12V line:

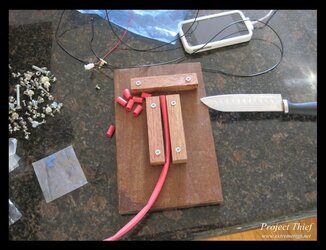

One thing I learned is that you don't have to join the wires all in the same place, in fact it's easier and less bulky if you join the 12V wires at one point, the 0V wires at another point and do the sleeving join at another point. This way you don't get one big lump. So don't do it like this is what I'm saying:

One side done - you can see the difference between the lumpy connection on the 3rd and 4th fan from the left, and the cleaner one on the 2nd/3rd:

Now we have to move those fans on to the other (push) side of the radiator. So we have to add the 140mm adapters to the other side of the fan, and remove the adapters from the original side:

All done with that side, now let's go do the same thing again for the pull side:

Attaching the fans for the pull side:

Nearly done - but the last piece of sleeve pulled out of the heatshrink:

Replaced that section and all done:

Installed - as you might be able to see, the section above with the low speed yates/HDDs still needs to be done:

As you can see there's still a ton to do in the bottom compartment:

This side that's open right now will house the ex560 that's currently being used for testing waterblocks, and the gtx 360 that I'm going to go wire up and sleeve right now

I have some ideas for lighting too that I'm going to test out also