- Joined

- Feb 1, 2011

- Location

- Republic of Texas

Here we go. I've posted some shop work practice runs previously regarding different tool uses for working out MB and case issues. Nothing extravagant but shoppy just the same.

Finally the image came together in my head, particularly now that my office has been remodeled (mostly, picking out the paint tonight or tomorrow). And have a little table set up to be my benching station. With that, I now need a benching station. Which this project will be an attempt to custom build.

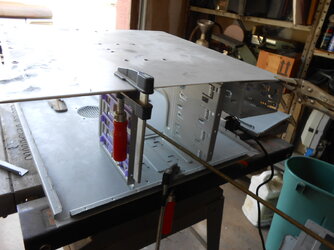

'Nuff said. I started with an old case, pulled it apart and am starting with some sheet metal from the right side of the case. I've been gathering some hardware which you'll see in the following pix. I will be attempting to make this station as adaptable and versatile as possible.

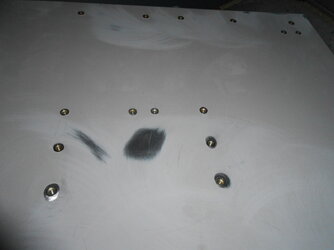

I laid out the MB tray using the original MB tray as a template so as to get the holes for the standoffs positioned correctly. Used a needle punch to get started:

Opened up the holes for 6-32 nut certs to 17/64":

Then drew the nut certs into place; there's a top shot and an underneath pic:

I'm using nut certs due to the versatility of having deep well threads, unlike a "normal" MB. This way I can get more stability and use a wider range of threaded products to attache a MB, cold cup, or who knows, spy antennae???

I have some brass plate and some steel sheet metal that I'm going to work into this. Got some articulating hose in mind too. Just need to find it....open to suggestions on that one.

Finally the image came together in my head, particularly now that my office has been remodeled (mostly, picking out the paint tonight or tomorrow). And have a little table set up to be my benching station. With that, I now need a benching station. Which this project will be an attempt to custom build.

'Nuff said. I started with an old case, pulled it apart and am starting with some sheet metal from the right side of the case. I've been gathering some hardware which you'll see in the following pix. I will be attempting to make this station as adaptable and versatile as possible.

I laid out the MB tray using the original MB tray as a template so as to get the holes for the standoffs positioned correctly. Used a needle punch to get started:

Opened up the holes for 6-32 nut certs to 17/64":

Then drew the nut certs into place; there's a top shot and an underneath pic:

I'm using nut certs due to the versatility of having deep well threads, unlike a "normal" MB. This way I can get more stability and use a wider range of threaded products to attache a MB, cold cup, or who knows, spy antennae???

I have some brass plate and some steel sheet metal that I'm going to work into this. Got some articulating hose in mind too. Just need to find it....open to suggestions on that one.

), was 107°F yesterday.

), was 107°F yesterday.