- Joined

- Dec 7, 2003

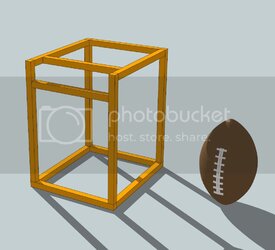

Exoframe Mini

Hi all,

*** Special Note. This the complete real time build log. If you wish to skip to the completed project, click --> Here <--. ***

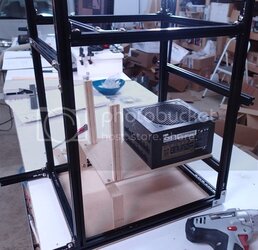

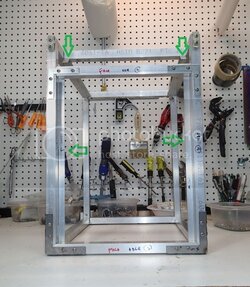

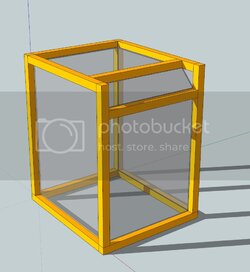

Time for my new project. This is my third visit to my Exoframe concept. so technically this would be the Exoframe 3.0.

Here is a link to the original Exoframe project.

http://www.overclockers.com/forums/showthread.php?t=597792

Here is a link to Exoframe 2.0.

http://www.overclockers.com/forums/showthread.php?p=7217964#post7217964

And a new twist for my modding. My first official sponsorship:

Unlike my previous two Exoframe based projects, this time I’m going compact!

Here are my goals:

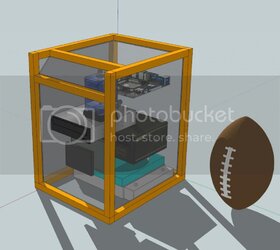

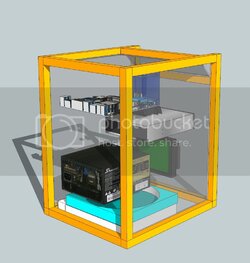

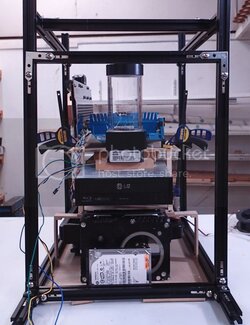

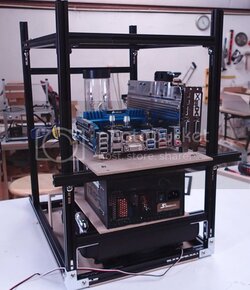

1) Gaming PC based on a Mini-ITX platform, full sized video card, full sized power supply.

2) Small size, appropriate for a Home Theater component.

3) Watercooled.

4) I already have all of my components:

Intel I7 2700k (Swiftech Apogee)

Asus P8Z77-I Deluxe

XFX 7970 (Heatkiller full cover sink)

Seasonic X750 power supply

LG Blu-ray burner

2x 4gb Corsair Vengeance RAM

Swiftech MCP35x pump with XSPC Pump/res top

Samsung 840 500gb SSD

Phobya 200mm radiator

Hi all,

*** Special Note. This the complete real time build log. If you wish to skip to the completed project, click --> Here <--. ***

Time for my new project. This is my third visit to my Exoframe concept. so technically this would be the Exoframe 3.0.

Here is a link to the original Exoframe project.

http://www.overclockers.com/forums/showthread.php?t=597792

Here is a link to Exoframe 2.0.

http://www.overclockers.com/forums/showthread.php?p=7217964#post7217964

And a new twist for my modding. My first official sponsorship:

Unlike my previous two Exoframe based projects, this time I’m going compact!

Here are my goals:

1) Gaming PC based on a Mini-ITX platform, full sized video card, full sized power supply.

2) Small size, appropriate for a Home Theater component.

3) Watercooled.

4) I already have all of my components:

Intel I7 2700k (Swiftech Apogee)

Asus P8Z77-I Deluxe

XFX 7970 (Heatkiller full cover sink)

Seasonic X750 power supply

LG Blu-ray burner

2x 4gb Corsair Vengeance RAM

Swiftech MCP35x pump with XSPC Pump/res top

Samsung 840 500gb SSD

Phobya 200mm radiator

Last edited: