-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PROJECT LOG The Powerful Pretty Pink Processor (aka, "The PPPP")

- Thread starter cpachris

- Start date

- Joined

- Nov 10, 2005

I wouldn't do them all just because of the amount of work involved, but doing a few that are going to be located in conspicuous places really does make them pop. I like it a lot.

I really don't think he is worried about the work involved doing them all, considering the amount of work he already has on the customizations of this build and in his BBBB.

I do think it would look better with the pink EK logo on all of them, just just to add to your work load on this, but as the standpoint of why short change the build with something this minuscule, when I'm sure you can do all these in a staged fashion like everything else while watching something like Game of Thrones, or some other show you have been meaning to catch up on.

- Joined

- Sep 7, 2013

Whatever happened to this project? Did it stall out? Is he not updating this thread anymore? Such an awesome build, I was looking forward to it getting closer to completion.

I thought it was done?

- Joined

- Nov 10, 2005

No, not done yet, and even his wife has bumped the thread over on OCN looking for updates.

- Joined

- Jun 28, 2012

his wife has bumped the thread over on OCN

I lol'd at this.

- Joined

- Sep 7, 2013

No, not done yet, and even his wife has bumped the thread over on OCN looking for updates.

Must be a busy man

- Joined

- Nov 10, 2005

Chris, has this been completed? Did you completely scrap the project and start over and were afraid of the public out cry?

- Joined

- Mar 26, 2012

- Location

- Edmond, OK

- Thread Starter

- #490

- Joined

- Sep 7, 2013

Back from the dead eh?

- Joined

- Jun 28, 2012

What a necro, where's your forum etiquette?!

I jest, glad to see you back Chris!

- Joined

- Mar 26, 2012

- Location

- Edmond, OK

- Thread Starter

- #493

- Joined

- Mar 26, 2012

- Location

- Edmond, OK

- Thread Starter

- #494

Hard to know exactly where to jump back in here. I'm out of practice.  I was greatly amused at the rumors of my possible incapacitation. And even more amused as some theorized that I must be busy doing taxes. Truth be told....there have been no accidents or illness that has sidelined me. Yes, work is busy....but no more so than for most of you. I am a CPA, but I don't do public accounting anymore, so it has nothing to do with year-end or tax season. What it really comes down to....is that I took a break. I never intended it to be this long....but it's easy to sink into different routines, habits and hobbies....and hard to change once you are there.

I was greatly amused at the rumors of my possible incapacitation. And even more amused as some theorized that I must be busy doing taxes. Truth be told....there have been no accidents or illness that has sidelined me. Yes, work is busy....but no more so than for most of you. I am a CPA, but I don't do public accounting anymore, so it has nothing to do with year-end or tax season. What it really comes down to....is that I took a break. I never intended it to be this long....but it's easy to sink into different routines, habits and hobbies....and hard to change once you are there.

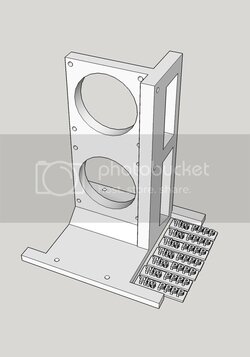

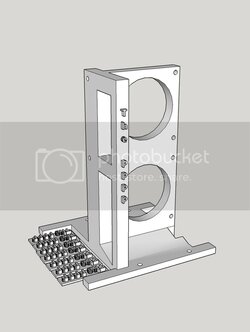

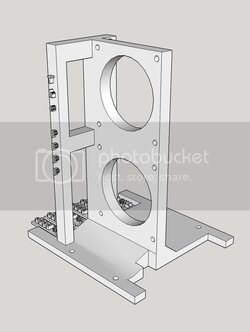

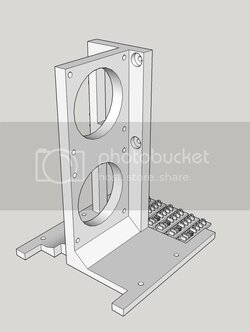

The break started when I had hit a sort of wall. Most of you will remember the supremely cool 3-d printing that I had gotten my hooks into. I have a friend that is in a 3-d print club, which gave me access to this groovy technology. I had quickly learned Google SketchUp and designed a pump stand for my dual pumps, and had even morphed it into a reservoir holder also. It was fun...and I loved the creativity that this new arena allowed. Well during the test fitting of my version 2 of the pump stand, it became clear that I had not allowed for enough space for the fittings that need to come out of the pump tops. The fittings hit the case window on the left side of the case. The pumpstand had to move from the position I had designed it for to allow room for the fittings....and this made it so that the reservoir was no longer centered in the front window of the case. Unacceptable! I started with design tweaks and intended to have a 3rd version of the pump stand printed....but encountered issues with getting it printed timely. My print takes between 30 and 45 hours to print...depending on the fill % used. Since I'm not an actual member of this club....I have to wait for periods of time when none of the members have prints running. That delayed me....and then the 3d printer itself was out of commission for awhile while a new extruder head was ordered. Anyway....I let this down time unfocus my efforts on this build.

But I'm back and ready to get this finished up. 3d printer is available once again. I was close to being done before my break......so my hope is this won't take long. I really only have to finish the plumbing, lighting, and window etching. Everything was running already....and the wiring/cabling was 95% done. This will be my first time bending acrylic tubing, but that will just make it more interesting for me.

I've already sent my latest model of the pump stand to the queue for the 3d printer, and it has been started. So I hope to have it back in a day or two. So.....to start this build thread going again....tonight I'll post some of images of version 3 of the pump stand. If you compare it with the pics of version 2...you'll easily see that the pumps themselves have had to shift back (to the right) so that more room is available between the left window and the pump tops.

Those little plates that say "The PPPP" are not attached to the pump stand at all. There was some extra room within the print envelope, so I thought....what the heck. I may use them to label a radiator....or harddrive....or something like that. We'll see.....

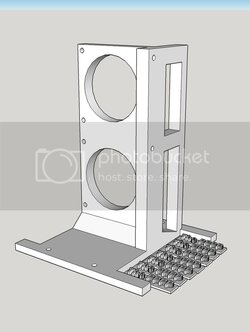

The notch in the base in the picture below is to hold and secure the GPU cabling that goes back down through the midplate.

In the picture below you'll see I had to counter sink the holes for the reservoir mount screws, since they reside right to the side of the pump tops now.

I also expanded the legs in front just a bit....to make sure there was room for the cold cathode inverter(s) that will sit right in front of the pump stand.

I should have the finished pump stand back soon....and I'll have pictures of it up quickly after that. While I wait....I'm going to finish painting the EK logo on those beautiful fittings. I had played around with doing that before....but now I need to finish them. Pictures of that tomorrow!

The break started when I had hit a sort of wall. Most of you will remember the supremely cool 3-d printing that I had gotten my hooks into. I have a friend that is in a 3-d print club, which gave me access to this groovy technology. I had quickly learned Google SketchUp and designed a pump stand for my dual pumps, and had even morphed it into a reservoir holder also. It was fun...and I loved the creativity that this new arena allowed. Well during the test fitting of my version 2 of the pump stand, it became clear that I had not allowed for enough space for the fittings that need to come out of the pump tops. The fittings hit the case window on the left side of the case. The pumpstand had to move from the position I had designed it for to allow room for the fittings....and this made it so that the reservoir was no longer centered in the front window of the case. Unacceptable! I started with design tweaks and intended to have a 3rd version of the pump stand printed....but encountered issues with getting it printed timely. My print takes between 30 and 45 hours to print...depending on the fill % used. Since I'm not an actual member of this club....I have to wait for periods of time when none of the members have prints running. That delayed me....and then the 3d printer itself was out of commission for awhile while a new extruder head was ordered. Anyway....I let this down time unfocus my efforts on this build.

But I'm back and ready to get this finished up. 3d printer is available once again. I was close to being done before my break......so my hope is this won't take long. I really only have to finish the plumbing, lighting, and window etching. Everything was running already....and the wiring/cabling was 95% done. This will be my first time bending acrylic tubing, but that will just make it more interesting for me.

I've already sent my latest model of the pump stand to the queue for the 3d printer, and it has been started. So I hope to have it back in a day or two. So.....to start this build thread going again....tonight I'll post some of images of version 3 of the pump stand. If you compare it with the pics of version 2...you'll easily see that the pumps themselves have had to shift back (to the right) so that more room is available between the left window and the pump tops.

Those little plates that say "The PPPP" are not attached to the pump stand at all. There was some extra room within the print envelope, so I thought....what the heck. I may use them to label a radiator....or harddrive....or something like that. We'll see.....

The notch in the base in the picture below is to hold and secure the GPU cabling that goes back down through the midplate.

In the picture below you'll see I had to counter sink the holes for the reservoir mount screws, since they reside right to the side of the pump tops now.

I also expanded the legs in front just a bit....to make sure there was room for the cold cathode inverter(s) that will sit right in front of the pump stand.

I should have the finished pump stand back soon....and I'll have pictures of it up quickly after that. While I wait....I'm going to finish painting the EK logo on those beautiful fittings. I had played around with doing that before....but now I need to finish them. Pictures of that tomorrow!

I just finished reading this entire log, umm WOW!! is about all I can say. Personally I wouldn't go for the color scheme (actually I would just not admitting that openly), but it rocks. I am curious though, you went to the trouble of powder coating the pass-through for the card reader but you forgot to do the GPU I/O plate  I was so sure you were gonna do that while reading through the last 25 pages. I can't say enough good things about your plans and how everything is turning out, I look forward to see the finished product.

I was so sure you were gonna do that while reading through the last 25 pages. I can't say enough good things about your plans and how everything is turning out, I look forward to see the finished product.

How in the world did I miss this Log in the first place, I really must live under a rock.

I'm subbed for the rest of the show.

I was so sure you were gonna do that while reading through the last 25 pages. I can't say enough good things about your plans and how everything is turning out, I look forward to see the finished product.

I was so sure you were gonna do that while reading through the last 25 pages. I can't say enough good things about your plans and how everything is turning out, I look forward to see the finished product. How in the world did I miss this Log in the first place, I really must live under a rock.

I'm subbed for the rest of the show.

- Joined

- Mar 26, 2012

- Location

- Edmond, OK

- Thread Starter

- #496

I just finished reading this entire log, umm WOW!! is about all I can say. Personally I wouldn't go for the color scheme (actually I would just not admitting that openly), but it rocks. I am curious though, you went to the trouble of powder coating the pass-through for the card reader but you forgot to do the GPU I/O plateI was so sure you were gonna do that while reading through the last 25 pages. I can't say enough good things about your plans and how everything is turning out, I look forward to see the finished product.

How in the world did I miss this Log in the first place, I really must live under a rock.

I'm subbed for the rest of the show.

Thanks t1! If I ever do another batch of items for powder coating, I agree it would make sense to do the GPU I/O also. I probably would even do the metal plates on the EK water blocks. But for now....moving forward.....

- Joined

- Mar 26, 2012

- Location

- Edmond, OK

- Thread Starter

- #497

Ok. I've got my helper, my paint, and my fittings. It's time to finish these up.

For those of you who haven't played with these EK fittings, they have a recessed EK logo on the circle portion. It's recessed enough so that you can get some paint down in there, and still have it all below the surface so that it doesn't get nicked up easily. It's almost like EK is begging me to put some pink in there! I'll oblige.

In my prevoius attempt, I was successful, but scraped up the face of the fittings way too much using an exacto knife to clean up the paint around the logo. I've experimented with a few approaches, and have one that works pretty well. I'm using a heavy body paint from Liquitex. Liquitex is awesome because they offer their full range of colors in all sorts of paints. I can use this same color in a soft body, medium body, heavy body, ink, spray paint, etc. For what I'm doing here today, the heavy body paint works best.

Get a little brush, and put a nice glob of paint all over the logo. Use the brush to ensure you've pushed paint down into the entire logo.....

Just a nice thick blob of paint over the logo. That's what you're after here....

Then, while it's still wet.....use a straightblade with a napkin or paper towel pulled tight around it....and scrape the blade over the top of the fitting. I'm using a ruler here....with a napkin pulled tight around it.

Since the logo is recessed, the ruler will wipe the paint off the fitting....while leaving a pool of it down inside the logo. It will look messy, but that is fine for now. You'll be tempted to try and wipe the blade back over the fitting again to get even more paint off. Don't. Every single time I tried this it would then start grabbing at some of the paint in the logo. Wipe it once....and set it down.

Let the paint dry completely like this.....

Here is my entire batch.....

Once the paint has dried completely....you'll notice that it has contracted just a little and pulled away from the logo edge and down inside the recessed portion. This is perfect.....

Now....get you some Q-tips and a bowl of Paint Thinner and a bowl of water.

Go to work by rubbing the Q-tips dipped in paint thinner around the face of the fitting. Just takes a little effort and you'll have removed all of the remaining paint of the face of the fitting......

Viola!

And the whole batch is done. Didn't take that long.....

Now....time for some fun up in the faux studio.....

It's an easy and fun mod to do with these EK fittings. Perfect way to add your accent color to your build if you are using these fittings.

I've got the 3d printed pump stand back from the printer! I'll show that off next......

For those of you who haven't played with these EK fittings, they have a recessed EK logo on the circle portion. It's recessed enough so that you can get some paint down in there, and still have it all below the surface so that it doesn't get nicked up easily. It's almost like EK is begging me to put some pink in there! I'll oblige.

In my prevoius attempt, I was successful, but scraped up the face of the fittings way too much using an exacto knife to clean up the paint around the logo. I've experimented with a few approaches, and have one that works pretty well. I'm using a heavy body paint from Liquitex. Liquitex is awesome because they offer their full range of colors in all sorts of paints. I can use this same color in a soft body, medium body, heavy body, ink, spray paint, etc. For what I'm doing here today, the heavy body paint works best.

Get a little brush, and put a nice glob of paint all over the logo. Use the brush to ensure you've pushed paint down into the entire logo.....

Just a nice thick blob of paint over the logo. That's what you're after here....

Then, while it's still wet.....use a straightblade with a napkin or paper towel pulled tight around it....and scrape the blade over the top of the fitting. I'm using a ruler here....with a napkin pulled tight around it.

Since the logo is recessed, the ruler will wipe the paint off the fitting....while leaving a pool of it down inside the logo. It will look messy, but that is fine for now. You'll be tempted to try and wipe the blade back over the fitting again to get even more paint off. Don't. Every single time I tried this it would then start grabbing at some of the paint in the logo. Wipe it once....and set it down.

Let the paint dry completely like this.....

Here is my entire batch.....

Once the paint has dried completely....you'll notice that it has contracted just a little and pulled away from the logo edge and down inside the recessed portion. This is perfect.....

Now....get you some Q-tips and a bowl of Paint Thinner and a bowl of water.

Go to work by rubbing the Q-tips dipped in paint thinner around the face of the fitting. Just takes a little effort and you'll have removed all of the remaining paint of the face of the fitting......

Viola!

And the whole batch is done. Didn't take that long.....

Now....time for some fun up in the faux studio.....

It's an easy and fun mod to do with these EK fittings. Perfect way to add your accent color to your build if you are using these fittings.

I've got the 3d printed pump stand back from the printer! I'll show that off next......

- Joined

- Sep 7, 2013

If only I used compression fittings in my loop. I would have done this. Deep blue would be my paint colour.

Neat trick Chris, thanks for sharing and yes, those fittings are sweet looking all done up like that!

Neat trick Chris, thanks for sharing and yes, those fittings are sweet looking all done up like that!

- Joined

- Mar 26, 2012

- Location

- Edmond, OK

- Thread Starter

- #499

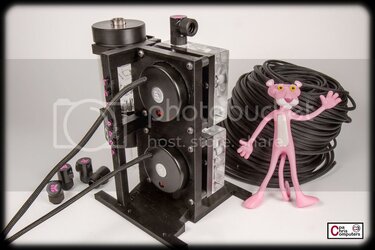

3D printed pump stand pictures!

Printing time was 36 hours for this version. The outside face is rougher than it was in the last two versions....but the bottom is absolutely flat this time with no warping. It was printed at 100% fill.....so this is one solid piece of plastic. It was printed in PLA....not ABS. Quite heavy. Here are some pictures from different angles...

In this closeup, you can see how the face of the pump stand looks. I may spend some time sanding some of the rougher edges....after I see what still shows once the pumps/tops/reservoir are mounted.

Now...to attach everything to the stand, I'll need some screws. The approach I've taken with my last few projects is to cut down my screws to size. It was hard for me to find the black socket head screws that I love so much....in every size that I might need. So instead, I bought about a thousand of these 30mm M4 Black Socket Head screws....and I just cut them down to whatever size is needed when I'm using them....

I just clamp then down in this little vise at the appropriate distance.....

...and then use the edge of the vise as a guide for the Dremmel to run across. Only takes about 10 seconds for a screw. Those little puppies sure do get hot in 10 seconds though....

Here are a couple of the freshly cut screws next to an original size screw, so you can see how much I was trimming to make these the perfect size for my recessed holes for the reservoir attachment. The edges usually are pretty rough....

....but they are smooth after running them along a file a few times. Those little rubber washers are what I'm going to add to help decouple the pumps and reservoir even further....

Here are a couple of shots of how the EK reservoir clamps fit onto the 3d printed pump stand. You can see that I designed recessed holes in the back of the pump stand for the nuts...because the pump tops would interfere if they stuck out at all....

Nice and flush.....

I decided to go ahead and test fit the entire thing.....so I cut some more screws, and mounted the pumps and reservoir to the 3d printed stand. Everything fit great! Here are some pictures from all angles.....

It is shockingly beautiful in person....the pump tops just look like huge chunks of glass. Everything fits together perfectly with no wasted space. There is a cutout that will allow for the cold cathode inverter, as well as a cutout for the GPU cables that was necessary to allow the stand to be snugged up closer to the motherboard.

The EK X3 reservoir is super high quality....

I brushed some pink paint on "The PPPP" raised lettering I designed in the pump stand....

It really came out as good as I was hoping. It's tight, compact, and beautiful. And it situates the pump tops at the perfect viewing angle for the left side window....and positions the reservoir at the perfect spot to be centered in the front window. I couldn't have done this with any pre-made stand. It really needed to be custom designed to pull this off. I love 3d printing.

I also brushed some paint on those badges that I had 3d printed. These could be used anyhwere....but I'm picturing them on the SSD's and/or radiators.

Next step is to drill some holes in the case midplate and bolt this baby in. Pictures soon!

Printing time was 36 hours for this version. The outside face is rougher than it was in the last two versions....but the bottom is absolutely flat this time with no warping. It was printed at 100% fill.....so this is one solid piece of plastic. It was printed in PLA....not ABS. Quite heavy. Here are some pictures from different angles...

In this closeup, you can see how the face of the pump stand looks. I may spend some time sanding some of the rougher edges....after I see what still shows once the pumps/tops/reservoir are mounted.

Now...to attach everything to the stand, I'll need some screws. The approach I've taken with my last few projects is to cut down my screws to size. It was hard for me to find the black socket head screws that I love so much....in every size that I might need. So instead, I bought about a thousand of these 30mm M4 Black Socket Head screws....and I just cut them down to whatever size is needed when I'm using them....

I just clamp then down in this little vise at the appropriate distance.....

...and then use the edge of the vise as a guide for the Dremmel to run across. Only takes about 10 seconds for a screw. Those little puppies sure do get hot in 10 seconds though....

Here are a couple of the freshly cut screws next to an original size screw, so you can see how much I was trimming to make these the perfect size for my recessed holes for the reservoir attachment. The edges usually are pretty rough....

....but they are smooth after running them along a file a few times. Those little rubber washers are what I'm going to add to help decouple the pumps and reservoir even further....

Here are a couple of shots of how the EK reservoir clamps fit onto the 3d printed pump stand. You can see that I designed recessed holes in the back of the pump stand for the nuts...because the pump tops would interfere if they stuck out at all....

Nice and flush.....

I decided to go ahead and test fit the entire thing.....so I cut some more screws, and mounted the pumps and reservoir to the 3d printed stand. Everything fit great! Here are some pictures from all angles.....

It is shockingly beautiful in person....the pump tops just look like huge chunks of glass. Everything fits together perfectly with no wasted space. There is a cutout that will allow for the cold cathode inverter, as well as a cutout for the GPU cables that was necessary to allow the stand to be snugged up closer to the motherboard.

The EK X3 reservoir is super high quality....

I brushed some pink paint on "The PPPP" raised lettering I designed in the pump stand....

It really came out as good as I was hoping. It's tight, compact, and beautiful. And it situates the pump tops at the perfect viewing angle for the left side window....and positions the reservoir at the perfect spot to be centered in the front window. I couldn't have done this with any pre-made stand. It really needed to be custom designed to pull this off. I love 3d printing.

I also brushed some paint on those badges that I had 3d printed. These could be used anyhwere....but I'm picturing them on the SSD's and/or radiators.

Next step is to drill some holes in the case midplate and bolt this baby in. Pictures soon!

- Joined

- Sep 7, 2013

WOW!

Best pump/res stand ever. really clean looking chris. Well done!

Best pump/res stand ever. really clean looking chris. Well done!

Similar threads

- Replies

- 2

- Views

- 614

- Replies

- 9

- Views

- 668