By way of update, I got some parts and waiting for some more.

Meanwhile, I redesigned my 9-Channel USB PWM Fan Controller to a 10 Channel USB PWM Fan controller with these extras:

1) 2x16 monochrome LCD support (software is WIP)

2) 2xstatus LEDS (for debugging. software is WIP, but i'll probably allow user-control)

3) Temp sensor (this modular/wired. so it can be put against motherboard/cpu/gpu/hdd/whatever)

I've also had some time to work on the firmware and software. I've basically re-written the app ground up in WPF (so I can make it look nicer later on)

Software now implements:

1) slider for fans

2) temperature readings

3) Fan calibration (i.e. tries duty cycles 0 -100 to see what duty cycles give what RPM/% fan speed)\

Software update:

While still waiting for the parts, I started preparing a breadboard. It resulted in a 150x100mm config for the 10 fans and other output/input (LED, LCD, Thermistor, ICSP).

(Pin headers for Fans missing, and the PIC18F4550 Those are the only parts I've been waiting on.

I went nuts here and decided to solder bridge everything. Was first time experimenting with this particular board. The pads make it fairly easy to solder bridge.

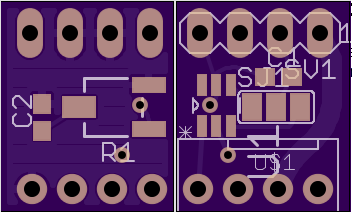

Although I liked the design and soldering outcome, I didn't like the size and decided to etch my own board. Having some extra spare time, I learnt how to use Eagle, re-designed the board, learnt (thanks internet!) how to etch boards, printed, got some copper clad and experimented a bit. For those who use Eagle, I've only used it 2 days now and REALLY hate the autorouter. It probably uses the worst algorithms there are. I tried a lot of times with different parameters but eventually just gave up. What you see on the board below is what I fully manually routed (yes, can probably improve).

I just now finally etched the board and cleaned it, and guess what... I got my parts earlier today! The only thing to progress this project further is to drill the newly baked pcb tomorrow, solder the parts. After that's done I'll have a complete prototyping board to fully work on the firmware and software.

(you will notice I forgot it's now a 10 channel fan controller, but still etched '9 channel' on it, it's just a typo )

Photo of PCB, iphone 4s and 250mL up&go for size comparison

Btw this is what I would call my "proper prototyping board". It wouldn't necessarily be what the end user would have/use. For example I've provided pin-outs for all the pins of the IC and also ICSP, which would normally not be included in a final product

Meanwhile, I redesigned my 9-Channel USB PWM Fan Controller to a 10 Channel USB PWM Fan controller with these extras:

1) 2x16 monochrome LCD support (software is WIP)

2) 2xstatus LEDS (for debugging. software is WIP, but i'll probably allow user-control)

3) Temp sensor (this modular/wired. so it can be put against motherboard/cpu/gpu/hdd/whatever)

I've also had some time to work on the firmware and software. I've basically re-written the app ground up in WPF (so I can make it look nicer later on)

Software now implements:

1) slider for fans

2) temperature readings

3) Fan calibration (i.e. tries duty cycles 0 -100 to see what duty cycles give what RPM/% fan speed)\

Software update:

While still waiting for the parts, I started preparing a breadboard. It resulted in a 150x100mm config for the 10 fans and other output/input (LED, LCD, Thermistor, ICSP).

(Pin headers for Fans missing, and the PIC18F4550 Those are the only parts I've been waiting on.

I went nuts here and decided to solder bridge everything. Was first time experimenting with this particular board. The pads make it fairly easy to solder bridge.

Although I liked the design and soldering outcome, I didn't like the size and decided to etch my own board. Having some extra spare time, I learnt how to use Eagle, re-designed the board, learnt (thanks internet!) how to etch boards, printed, got some copper clad and experimented a bit. For those who use Eagle, I've only used it 2 days now and REALLY hate the autorouter. It probably uses the worst algorithms there are. I tried a lot of times with different parameters but eventually just gave up. What you see on the board below is what I fully manually routed (yes, can probably improve).

I just now finally etched the board and cleaned it, and guess what... I got my parts earlier today! The only thing to progress this project further is to drill the newly baked pcb tomorrow, solder the parts. After that's done I'll have a complete prototyping board to fully work on the firmware and software.

(you will notice I forgot it's now a 10 channel fan controller, but still etched '9 channel' on it, it's just a typo )

Photo of PCB, iphone 4s and 250mL up&go for size comparison

Btw this is what I would call my "proper prototyping board". It wouldn't necessarily be what the end user would have/use. For example I've provided pin-outs for all the pins of the IC and also ICSP, which would normally not be included in a final product

Last edited: