- Thread Starter

- #41

The DSP is inside the fan motor. Look up "sensorless field oriented control" if you want to know more.

and what about the one you have in sign? has it a built in DSP or it's different?

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

The DSP is inside the fan motor. Look up "sensorless field oriented control" if you want to know more.

Plug the PWM mate motherboard header into the motherboard fan header.

Plug the fan into the PWM mate fan header.

Done!

It's a good idea, but now it's too late as I have bought so many resistors that I'll go with trial and error, even calculating is not very effective as the real current is quite different from the one printed on the fan (apart from the tolerance thing)need to mind you that the rheostat might got hot (probably way to hot so it might give away).

but on the bright side, you can determine what's the best resistor value to match your need, then replace it with the proper wattage resistor.

IMO, this will much be easier than dealing with calculating things that had tolerances

If you are talking about the pwm controller, I have already solved that as I have bought a Zalman PWM fan mate, that works pretty good...but it's not enough!but I think you should consider WhitehawkEQ or Bobnova offer for the controller if you can't build one for yourself.

it works much better than anything else available in the market today

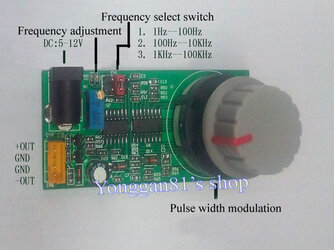

If i was to buy one of these PWM generators : http://www.ebay.ie/itm/PWM-0-90-Fre...062794?hash=item1ea25d9c8a:g:uqYAAOSwBLlVUHVW

I'm sure i can supply 5V by this cable http://www.ebay.ie/itm/1m-USB-to-DC...633540?hash=item2c9adb70c4:g:G6QAAOSwEeFVTm2W from internal usb in the server.

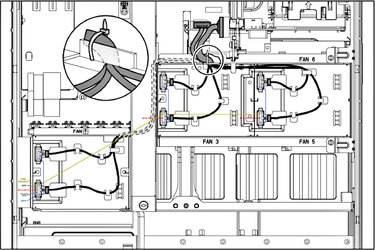

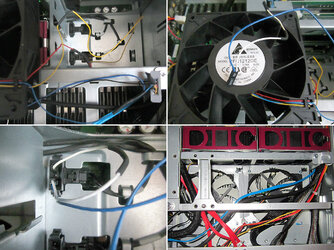

Second thing, the fans that are in the server are: PFC0612DE http://partner.delta-corp.com/Products/FANUploads/Specification/PFC0612DE-F00(REV02).pdf From the specs i can read "The preferred operating point for the fan is 25kHz"

PWM generator i linked to earlier on has a range selection. Will this work if i select range between 1kHz - 100kHz?

If i have 5 fans to control, can i connect all of them to one PWM output?

JUst by looking on the picture, Where do i connect "GND from the generator" to?