- Joined

- Mar 5, 2012

- Location

- Arizona, USA

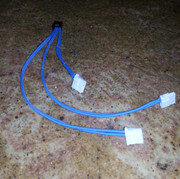

Not a stranger to sleeving but in this case I'm having one hell of a time wrestling the new pins into the Seasonic mini-fit connectors, currently I'm at about 25% success rate getting them back into the mini-fit after sleeving on 18 AWG with 550 paracord. Is there a trick I'm missing or am I just getting impatient. It seems that the paracord is bunching at the mini-fit which prevents it from locking in. I get ~1mm from locking in almost every time but if I try to work it in further, I've been bending the terminals at the crimp area and the frustration factor is increasing here

Please tell me there's a trick I'm missing here (not holding my tongue out at the proper angle?) since this is my first attempt at heatshrinkless paracord sleeving (trying to stay away from heatshrink for this project)

Please tell me there's a trick I'm missing here (not holding my tongue out at the proper angle?) since this is my first attempt at heatshrinkless paracord sleeving (trying to stay away from heatshrink for this project)