- Joined

- Dec 19, 2012

I recently started with Extreme cooling and have had a few mishaps along the way. So I decided to post a technique I have found quite effective for the life span of my parts. This isn't a "How to Prep your Mobo" thread. This starts under that!

I bought all my equiptment from BMWBaxter but it didn't come with instructions. He had this board that you could put the motherboard onto and it was cool but after using it a few times I found there were things i liked and things I didn't. So I made one of my own.

The first thing I learned is how terrible I did waterproofing the first time. Do yourself a favour and read the guides, they're full of valuable info and will save your parts. Keeping the air out is the key. If it isn't airtight, the water will get in!

Let's get to it.

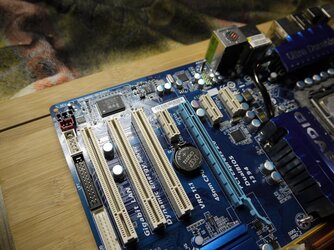

I started with a bamboo cutting board from the dollar store for $3, marked it out for the motherboard i'll be using, which is a Z87 Hero 1150 socket. The one in the pics is a Giga EP45, it was handy and not in use at the time.

Here you see the board marked out, prepped for the drill.

I used a 1/2 inch forstner bit to countersink the bolt holes.

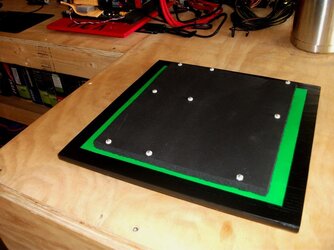

Here's a couple pics of the finished product, as you see by the backside shot, I counter sunk 4 holes around the socket. I found that the back plate for the pot gets very cold and attracts a lot of water so I eliminated it all together and just use some threaded rods with a nut and washer.

A bunch of 6x32 screws, washers and nuts.

Test fit.

Cutting a new piece of insulation. This was a workout mat that I picked up cheap. You wan to get good closed cell foam like this.

Trimming the foam. i like to leave a bit of extra to help seal around the edge of the board.

Almost done.

I oil the cutting oard to help keep it from holding water.

I bought all my equiptment from BMWBaxter but it didn't come with instructions. He had this board that you could put the motherboard onto and it was cool but after using it a few times I found there were things i liked and things I didn't. So I made one of my own.

The first thing I learned is how terrible I did waterproofing the first time. Do yourself a favour and read the guides, they're full of valuable info and will save your parts. Keeping the air out is the key. If it isn't airtight, the water will get in!

Let's get to it.

I started with a bamboo cutting board from the dollar store for $3, marked it out for the motherboard i'll be using, which is a Z87 Hero 1150 socket. The one in the pics is a Giga EP45, it was handy and not in use at the time.

Here you see the board marked out, prepped for the drill.

I used a 1/2 inch forstner bit to countersink the bolt holes.

Here's a couple pics of the finished product, as you see by the backside shot, I counter sunk 4 holes around the socket. I found that the back plate for the pot gets very cold and attracts a lot of water so I eliminated it all together and just use some threaded rods with a nut and washer.

A bunch of 6x32 screws, washers and nuts.

Test fit.

Cutting a new piece of insulation. This was a workout mat that I picked up cheap. You wan to get good closed cell foam like this.

Trimming the foam. i like to leave a bit of extra to help seal around the edge of the board.

Almost done.

I oil the cutting oard to help keep it from holding water.