- Joined

- Feb 25, 2015

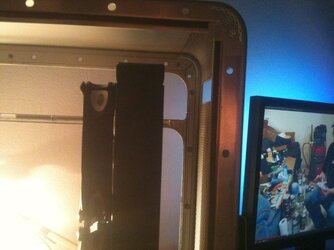

So, i decided to finally put my hands on Powermac G5 case, and build my dream computer / cooling system.

And finally ! Few days ago, there it was, one ad got my attention, Powermac 7.3, with LCS, non functional ( LCS drained out all over the PPCs and PSU ), i was happy as hell

Aaand in less than 36hours, here it is DHL knocked on my doors, yeeeeeeeeei

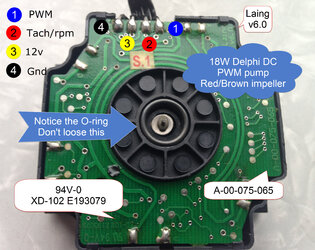

LCS was of course malfunctioned, but no worries my friends! Pump is still functional... Great deal, considering only pump would cost me much more than i paid for delivery + item.

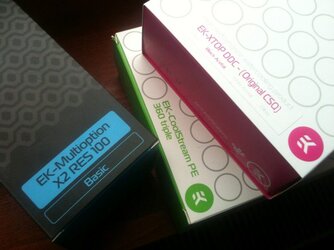

So here it is, sweet little DDC guy

As i was talking with seller about our deal, i worked on 3d sketch for my project in the same time, and here it is.

Front

Back

Renders

My dream is to build as quiet as possible, yet well cooled and re-usable case / cooling system that will fit to any motherboard / gpu / cpu configuration in future.

So, what are these compartments inside of it ? Well, i had in mind to use only 3 fans to cool whole pc, and to achieve maximum airflow / cooling effect without any additional fans except these on water radiator.

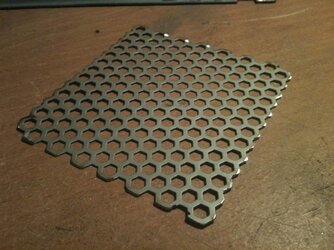

So in this build i will go with fanless PSU, 3 x 120 NoiseBlocker Bionic eLoop fans on pwm and i will try to make thermal zones, so fans can speed up individually if there is a problem with temperature arise in one of the compartments without need to speed up another 2 fans. Apple Powermac case is perfect for build like this, as his perforated front and back side are ideal for vertical radiator placement and it will enable me to do what i want. Also i think that build quality is well known, this thing is built like a tank

* reserved *

-----------------------------------------

HW

* Other still unknown *

RAM: Avexir Core A Type

PSU: Silverstone Nightjar 520

-----------------------------------------

LCS HW

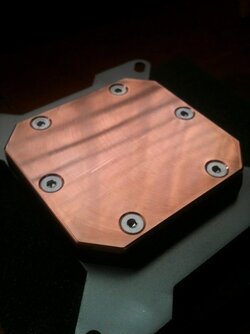

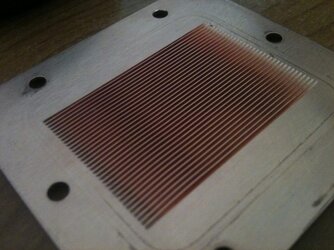

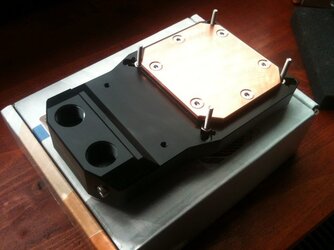

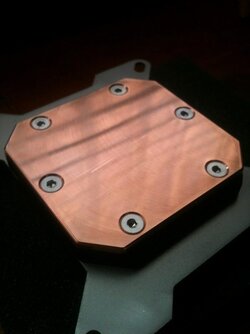

Watercool HK CPU Rev. 3.0 LC

Watercool HEATKILLER® GPU-X3

EK-CoolStream PE 360 3 * 120 mm radiator ( 19FPI double fin )

Noiseblocker NB-eLoop B12-PS Bionic

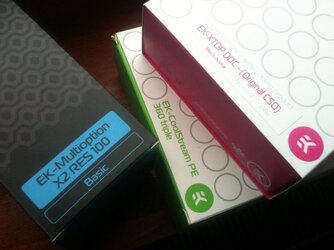

EK-XTOP DDC - Acetal (Original CSQ)

EK-DDC Heatsink Housing

Alphacool tubing AlphaTube black

Monsoon 13/10mm (ID 3/8" OD 1/2") white fittings

IceModz cable managment - white, black and grey sleeve combination

-----------------------------------------

- - - Updated - - -

I decided to pull out all things from it, and leave the rest for tomorrow, but Battlefield 4 servers were swarmed with children that day, so i decided to take a closer look on LCS pump, and to see if that machinery is still working.

Ewwwww

I had to clean that crap out

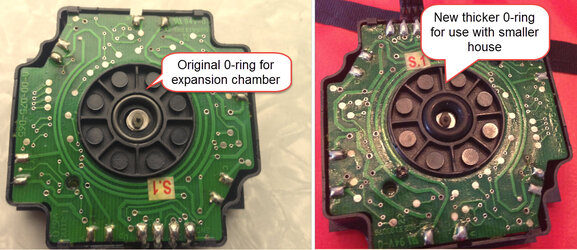

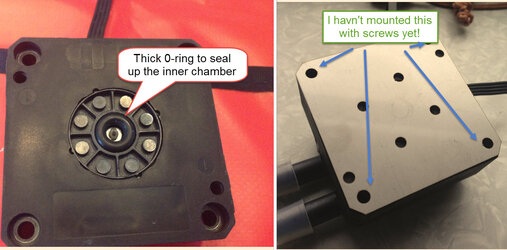

What the heck? What kind of Laing pump is this ? Well, one with volumetric compensator

Crap that got stuck inside pump, some debris, rust and who know what... I actually found something that was similar to pineapple chunks ( i don't want to know what that is xD )

Case is 90% cleaned out, i have to wait for my Dremel tool to arrive to continue work on it.

And for the end of that night, random workplace pic, i was 50hours awake because of some other projects / work, and that was all for this night. Time to sleep

Current status:

* Waiting for Dremel tool delivery

* Waiting for some cash to buy remaining parts

* Waiting for sponsors to arrange parts sponsorships ( Don't worry, i have this project 100% covered by myself, but sponsor are always welcome

P.S. Sorry for grammar mistakes, English isn't my native language

Last edited: