- Joined

- Oct 5, 2013

PROJECT VF8

Hi! I would like to start my next scratch build project!

My main idea is to have really own and unique design of big tower case

Placing motherboard in unusual position - connectors will be located down in the case.

Also I want fit there two 480 radiators for best cooling performance.

Next part is interconnect acrylic panel for coolant between top and bottom part of case - CNC machined hopefully

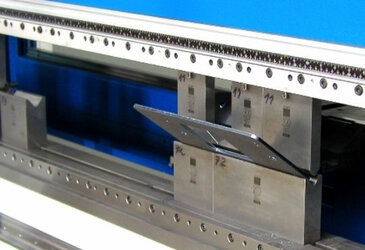

As in my previous project this will be lasercutted mostly too.

There will be used same folding system as in my previous project.

I am not sure about final color theme (fluid, fans, etc.) so I decided to not show final render of project.

So I will always share only next part of build rendered.

This time is main frame of case

About the color theme.

My most favourite is black inside, white outside and coolant red or white pastel with Aurora booster.

Coolant color depends mostly on platform Z97 (Formula VII) - red, X99 (Deluxe) - white.

Materials:

Steel

Aluminium

Acrylic

Capacity:

Position for two 480 mm radiators (60 mm and 30 mm thickness)

ATX motherboard

Three positions for 2,5" SSDs and one position for 3,5" HDD

Position for two D5 pumps

Computer will be again water-cooled using products from the best companies.

Components:

Intel i7 4790K

ASUS Formula VII

ASUS GTX970 SLI

PSU V1000 CoolerMaster

SSD and RAM undecided

JetFlow and FP 120 FANs by CoolerMaster

and also watercooling, but about it another time..

Proudly sponsored by these amazing companies!

In this time I am working on two another projects, so I will try to add more very soon! Here is first batch of lasercutted parts

Finally someone who has a sense of humor, that cat must be patient to let you put him in there.

Finally someone who has a sense of humor, that cat must be patient to let you put him in there.