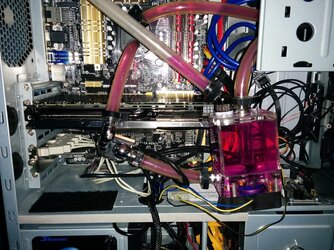

So I picked up a 780ti with full cover waterblock. I knew it would be longer than that 660ti it replaces, but I guess I didn't exactly realize by how much. This is the old setup:

The new card extends all the way to the edge of the back of the upper drive bay area, which is where the lines for the radiator need to go.

The case isn't QUITE wide enough to put the pump next to the card, otherwise I'd do exactly that. I could put a 45deg or 60deg rotary fitting on the pump inlet and hope that the tubing doesn't kink as it makes the turn. I could also cut a hole in the bottom of the drive bay area and route the tubing that way, but that would require disassembling the entire rig to avoid getting metal shavings where they don't belong.

Another solution involves finding a new pump with restop that's a little shorter so that it fits under the card. The pump is 6 years old, but it shows no signs of trouble. Something like this might fit (I'd need to measure to be certain). My current pump+res combo is 96mm per specs and is just barely too tall. This one is listed at 90mm tall.

http://www.frozencpu.com/products/1..._Blue_LED_Light_-_Acrylic.html?tl=g30c107s152

Does anybody see other solutions that retain most of the existing equipment? New fittings wouldn't be much trouble to get. A new pump/res combo would be a less desirable but doable option.

The new card extends all the way to the edge of the back of the upper drive bay area, which is where the lines for the radiator need to go.

The case isn't QUITE wide enough to put the pump next to the card, otherwise I'd do exactly that. I could put a 45deg or 60deg rotary fitting on the pump inlet and hope that the tubing doesn't kink as it makes the turn. I could also cut a hole in the bottom of the drive bay area and route the tubing that way, but that would require disassembling the entire rig to avoid getting metal shavings where they don't belong.

Another solution involves finding a new pump with restop that's a little shorter so that it fits under the card. The pump is 6 years old, but it shows no signs of trouble. Something like this might fit (I'd need to measure to be certain). My current pump+res combo is 96mm per specs and is just barely too tall. This one is listed at 90mm tall.

http://www.frozencpu.com/products/1..._Blue_LED_Light_-_Acrylic.html?tl=g30c107s152

Does anybody see other solutions that retain most of the existing equipment? New fittings wouldn't be much trouble to get. A new pump/res combo would be a less desirable but doable option.