It's about time I finally got around to posting some pics of this beast, well beast might be slightly over reaching, it's a tame kitten really with a massive water problem. Ok, so none of that is true, it's just a venture into water cooling that started here about a year ago reading everything I could and asking so many of the same questions others have asked, and then I don't take your advise and end up doing my own thing. What started off as a fun project of building a good gaming computer a lil over a year ago turned into (so far) a really nice water-cooled PC.

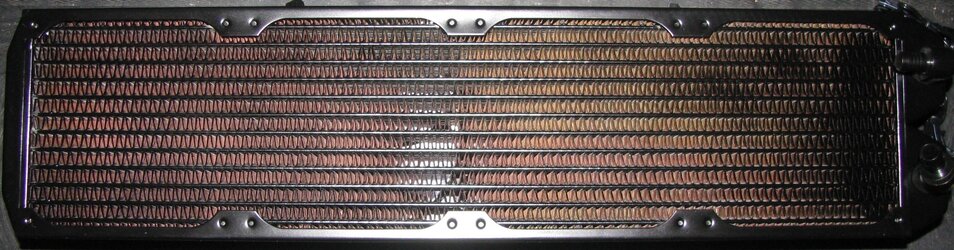

This is how it started, well actually it started as a single gpu build but I always wanted a multi GPU PC so it got one pretty quick. Then all the planning and reading of darned near every thread and review of different blocks, radiators, fans, pump and anything else that could be crammed into a water loop.

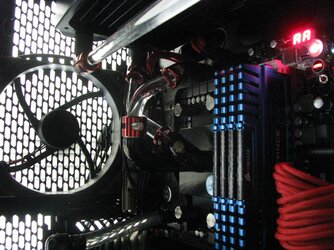

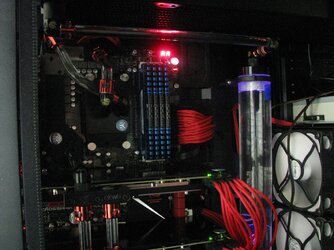

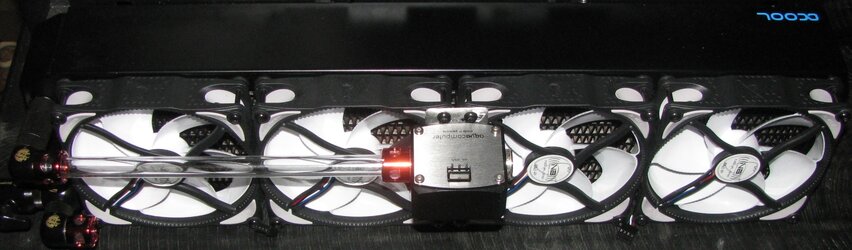

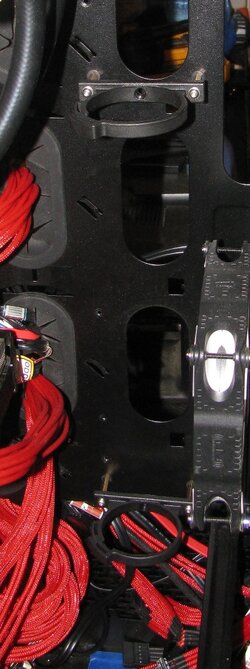

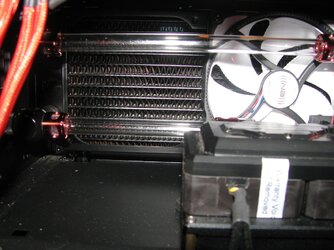

I went with EK blocks, while I like the look of some of the other brands out there, I like the simplistic looks for this build, and it seemed they were close to the best performing (like the 1-2c difference across the board was that big). I also wanted to give a shot at acrylic tubing, but I'm not a fan of rubber o-ring and compression fittings for hard tubing, so I went with the monsoon glue it all together it ain't breaking unless you want it broken fittings. The Acrylic isn't that hard to bend, but it's pretty touchy if you apply too much heat for too long the gases inside will separate and form bubbles inside the tubing (wasted a foot of tubing cause of that).

The fittings are pretty easy to use, glue is nice that it doesn't set unless it's put in sunlight UV rays. Easy to seal with these fittings.

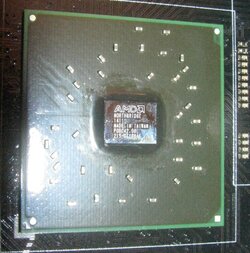

I've never taken the coolers off GPUs before so I was pretty hesitant, but a lot of reading and the if it's going to break just get it over with attitude got me from this:

More updates to come.

This is how it started, well actually it started as a single gpu build but I always wanted a multi GPU PC so it got one pretty quick. Then all the planning and reading of darned near every thread and review of different blocks, radiators, fans, pump and anything else that could be crammed into a water loop.

I went with EK blocks, while I like the look of some of the other brands out there, I like the simplistic looks for this build, and it seemed they were close to the best performing (like the 1-2c difference across the board was that big). I also wanted to give a shot at acrylic tubing, but I'm not a fan of rubber o-ring and compression fittings for hard tubing, so I went with the monsoon glue it all together it ain't breaking unless you want it broken fittings. The Acrylic isn't that hard to bend, but it's pretty touchy if you apply too much heat for too long the gases inside will separate and form bubbles inside the tubing (wasted a foot of tubing cause of that).

The fittings are pretty easy to use, glue is nice that it doesn't set unless it's put in sunlight UV rays. Easy to seal with these fittings.

I've never taken the coolers off GPUs before so I was pretty hesitant, but a lot of reading and the if it's going to break just get it over with attitude got me from this:

More updates to come.

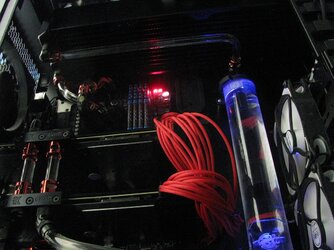

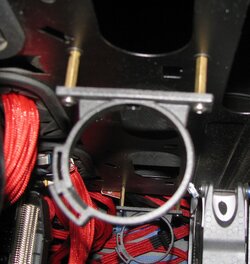

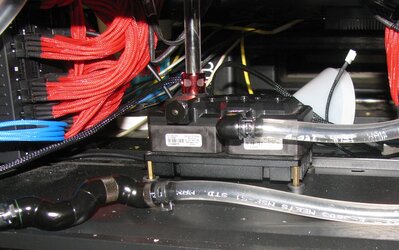

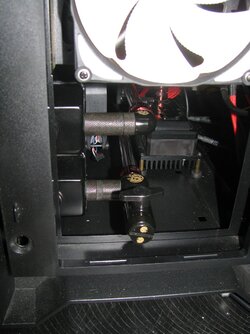

So long as it doesn't move I'll be happy. Mounting that res was another story, with the hardline tubing and I didn't want a bend there I had to place stand-offs for the res holders to get the distance right, it just so turns out with .5mm washers and 15 or 20mm stand-offs it puts the res in just the right spot for a nice simple drop of water to the pumps. If you plan on doing any work, have the right tools, or just have tools powerful enough to the job with minimal effort.

So long as it doesn't move I'll be happy. Mounting that res was another story, with the hardline tubing and I didn't want a bend there I had to place stand-offs for the res holders to get the distance right, it just so turns out with .5mm washers and 15 or 20mm stand-offs it puts the res in just the right spot for a nice simple drop of water to the pumps. If you plan on doing any work, have the right tools, or just have tools powerful enough to the job with minimal effort.

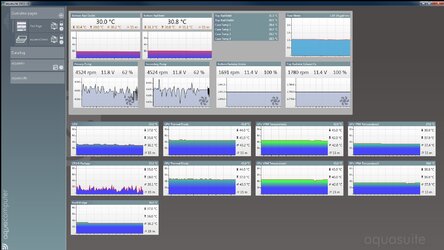

We shall see.

We shall see.

Anyhow, it's picture time

Anyhow, it's picture time