- Joined

- Apr 3, 2015

- Location

- Planet Earth

- Thread Starter

- #41

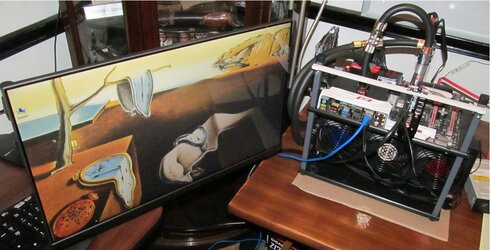

Hacking The Details...

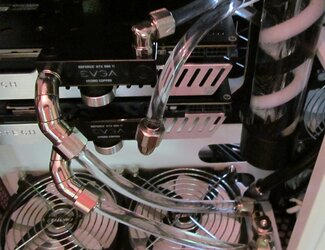

So this is it, right? I am already to go!

I got the G7/6700k on TheBianch.

I got all the parts and fittings.

EVERYTHING!

But wait!

As I look pondering...visualizing it all, I have one glaring problem I can't live with.

And its the biggest run in both loops...

So here is the story of what is hopefully the last major Hack on this case...

Basically, I need a port hole for the run. I could run it over the outside of the edge, but...

NOT! You have to Hack the Details!!

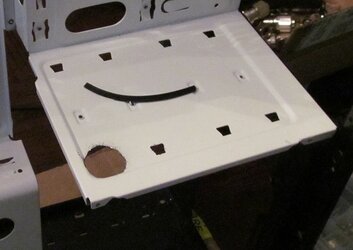

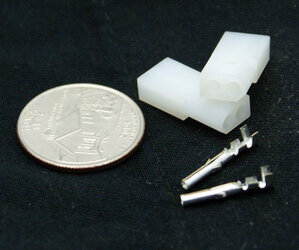

So the quarter is the intended hole.

So I love this case more and more every day!

I was WTF, how do I get in there to even do this!?

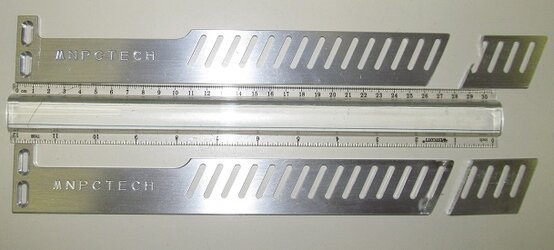

Well, as I mentioned mefore, very few rivets in this case

See all the screws?

And 25 screws later...

The whole ding-dang-a-lang top comes off without having to remove the rads/fans!!

Sweet!!

So now to work.

So OK, I know that bit is not designed to cut metal.

I don't think it will cut anything anymore

I will leave out where I had to relocate downstairs

and really hack out this hole with secret tools and methods.

read: "needle nose pliers, dikes, rat tail file, cursing and finally some dremel action"

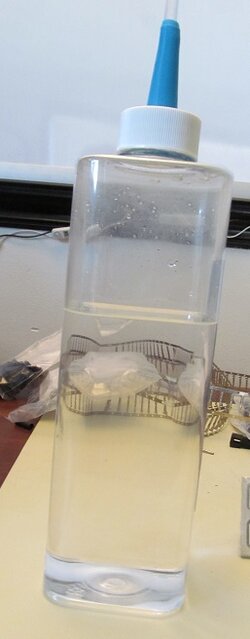

I was gonna use this u-channel stuff that I got sometime ago that has the preasure activated adhesive.

Well for something this small, it does not work!!!

It is pretty stiff, and when you start to work it and bend it, it activates from the generated heat and is impossible to work with.

So made a bigger hole and swapped over one of the factory rubber port grommet thingys

Turned out ok. I other port is not visible and will be fine for wires/etc.

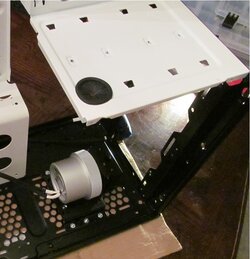

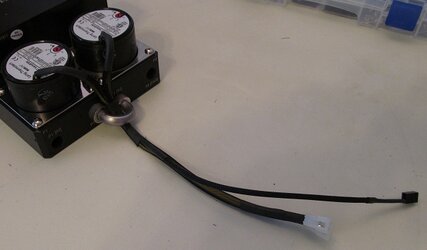

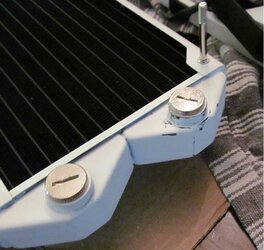

Was able to finally mount the second pump appropriately, kinda...

Its not a factory mount point for the pump bracket.

Its actually on rad mounts for an optional rad location.

The two default factory pump bracket locations were eliminated due to set-up.

So, again had to improvise...

And 25 screws later....

So, that was kinda a process and took some time, but in the end I think worth it.

Now I can FINALLY make that run, and plumb this rig.

Hasta la Proxima

So this is it, right? I am already to go!

I got the G7/6700k on TheBianch.

I got all the parts and fittings.

EVERYTHING!

But wait!

As I look pondering...visualizing it all, I have one glaring problem I can't live with.

And its the biggest run in both loops...

So here is the story of what is hopefully the last major Hack on this case...

Basically, I need a port hole for the run. I could run it over the outside of the edge, but...

NOT! You have to Hack the Details!!

So the quarter is the intended hole.

So I love this case more and more every day!

I was WTF, how do I get in there to even do this!?

Well, as I mentioned mefore, very few rivets in this case

See all the screws?

And 25 screws later...

The whole ding-dang-a-lang top comes off without having to remove the rads/fans!!

Sweet!!

So now to work.

So OK, I know that bit is not designed to cut metal.

I don't think it will cut anything anymore

I will leave out where I had to relocate downstairs

and really hack out this hole with secret tools and methods.

read: "needle nose pliers, dikes, rat tail file, cursing and finally some dremel action"

I was gonna use this u-channel stuff that I got sometime ago that has the preasure activated adhesive.

Well for something this small, it does not work!!!

It is pretty stiff, and when you start to work it and bend it, it activates from the generated heat and is impossible to work with.

So made a bigger hole and swapped over one of the factory rubber port grommet thingys

Turned out ok. I other port is not visible and will be fine for wires/etc.

Was able to finally mount the second pump appropriately, kinda...

Its not a factory mount point for the pump bracket.

Its actually on rad mounts for an optional rad location.

The two default factory pump bracket locations were eliminated due to set-up.

So, again had to improvise...

And 25 screws later....

So, that was kinda a process and took some time, but in the end I think worth it.

Now I can FINALLY make that run, and plumb this rig.

Hasta la Proxima

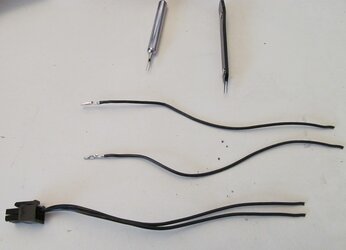

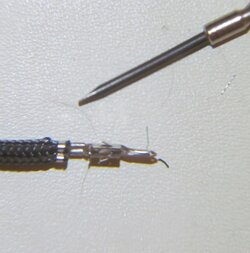

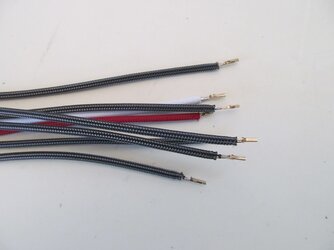

Please sleeve up some custom cables then! They would really look good and I plan on sleeving my PSU cables one day as well.

Please sleeve up some custom cables then! They would really look good and I plan on sleeving my PSU cables one day as well. AWESOME!

AWESOME!