- Joined

- Sep 11, 2015

I'm back again looking for more advice

Unfortunately I wasn't able to go through with watercooling a couple of months ago when I posted here in the first place. With tax returns just around the corner though, I'm going to start setting aside some money and finish it with a chunk of that. I've had quite a few ideas since I last drew up a layout guide and would love some pointers.

My components:

Case - Corsair 760T (white)

Motherboard - Gaming 7 Z97X (Gigabyte)

CPU - Intel 4790k

GPU - Diamond R9 295x2 (one for now, looking to pick up another one within the year)

RAM - EVGA SuperSC 2x8G 2400

PSU - Lepa G1600w

Parts I'm looking at:

Res - XSPC Photon 270

Pump - Swiftech MCP655 Series 12 VDC D5 Water Pumps - With Speed Control

Pump Top - EK-XTOP Revo D5 Pump Body - Plexi

CPU Block - Swiftech APOGEE XLC Clear

GPU Block - EK Radeon Radeon R9-295X2 VGA Liquid Cooling Block - Nickel

420 Rad - Black Ice Nemesis 420GTS Ultra Stealth U-Flow - Primer

280 Rad - Black Ice Nemesis 280GTS Ultra Stealth U-Flow - Primer

T Fitting - (2) - XSPC G1/4 black chrome

Res Top Adapter - (1) - XSPC M20 to G1/4 fillcap adapter - black chrome

Straight Fittings - (18) - Bitspower G1/4 matte black for acrylic tube OD 12MM (BP-MBEML)

Valve fitting - (2) - EK-AF Ball Valve (10mm) G1/4 - Black Nickel

Tubing - Bitspower non-champher Crystal Link 12MM OD

Coolant - To be decided, most likely an opaque white

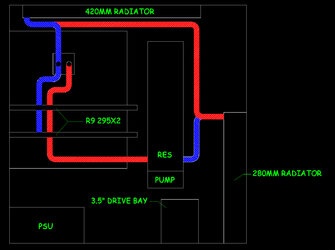

Diagram:

Basically, the water would go pump/res -> 280 rad -> 420 rad -> cpu, gpu1, gpu2 in parallel -> pump/res

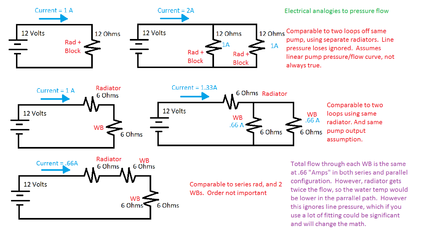

As the R9 295x2 blocks cover both chips in series, I'm assuming the flow rate would be much lower through these than the CPU block. I was thinking about putting a valve between the input of the CPU block and the T fitting that splits the loop. If I do this, I can fiddle with it slowly afterwards to try to limit the flow to the CPU block to about the same if not slightly less than the GPU's. Opinions?

Unfortunately I wasn't able to go through with watercooling a couple of months ago when I posted here in the first place. With tax returns just around the corner though, I'm going to start setting aside some money and finish it with a chunk of that. I've had quite a few ideas since I last drew up a layout guide and would love some pointers.

My components:

Case - Corsair 760T (white)

Motherboard - Gaming 7 Z97X (Gigabyte)

CPU - Intel 4790k

GPU - Diamond R9 295x2 (one for now, looking to pick up another one within the year)

RAM - EVGA SuperSC 2x8G 2400

PSU - Lepa G1600w

Parts I'm looking at:

Res - XSPC Photon 270

Pump - Swiftech MCP655 Series 12 VDC D5 Water Pumps - With Speed Control

Pump Top - EK-XTOP Revo D5 Pump Body - Plexi

CPU Block - Swiftech APOGEE XLC Clear

GPU Block - EK Radeon Radeon R9-295X2 VGA Liquid Cooling Block - Nickel

420 Rad - Black Ice Nemesis 420GTS Ultra Stealth U-Flow - Primer

280 Rad - Black Ice Nemesis 280GTS Ultra Stealth U-Flow - Primer

T Fitting - (2) - XSPC G1/4 black chrome

Res Top Adapter - (1) - XSPC M20 to G1/4 fillcap adapter - black chrome

Straight Fittings - (18) - Bitspower G1/4 matte black for acrylic tube OD 12MM (BP-MBEML)

Valve fitting - (2) - EK-AF Ball Valve (10mm) G1/4 - Black Nickel

Tubing - Bitspower non-champher Crystal Link 12MM OD

Coolant - To be decided, most likely an opaque white

Diagram:

Basically, the water would go pump/res -> 280 rad -> 420 rad -> cpu, gpu1, gpu2 in parallel -> pump/res

As the R9 295x2 blocks cover both chips in series, I'm assuming the flow rate would be much lower through these than the CPU block. I was thinking about putting a valve between the input of the CPU block and the T fitting that splits the loop. If I do this, I can fiddle with it slowly afterwards to try to limit the flow to the CPU block to about the same if not slightly less than the GPU's. Opinions?

Last edited: