- Joined

- Nov 3, 2015

Hello all,

Everybody knows it's cool to have LEDs in your case, whether in strips or otherwise. It's even cooler to be able to control these, namely brightness if you only have one color. There are 5.25" bay control solutions, but as an owner of a case without such a bay, I'm looking for a different solution for brightness control. I have some experience using an Arduino to PWM a small LED around 1000Hz, but I'm looking for a bigger better solution for more LEDs and from a different PWM source. As an aerospace engineer, I don't know as much about semiconductors and their implementations as some of you guys out here, so I was hoping for some guidance on what I think is a pretty cool idea.

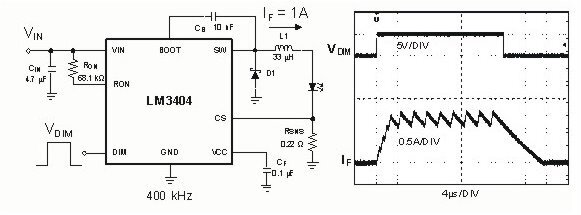

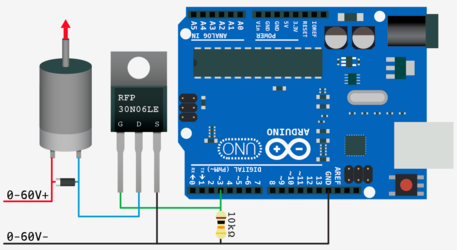

PWM motherboard fan headers provide usually a 25kHz PWM signal at 5v and 5mA from 0-100% duty cycle, something ideal for PWM fans to read and be controlled by. However, I think this PWM source would be ideal for LED control. The challenge is "amplifying" that PWM source to a 12V signal between 1-2A for a good number of LEDs. My experience tells me there should be a relatively simple implementation of a MOSFET or bipolar junction transistor to use the 5v signal to switch a 12v signal to power the lights, but I don't know what other details need to be considered here. I know this type of modulation exists in LED drivers and stepper motor drivers, but I'm looking to implement it in this case.

I hope somebody who has more semiconductor experience can lend some guidance, I think this would be a super cool thing to have implemented because then you could for instance set up a profile in speedfan or control it manually or all these things, and even control an RGB strip if you have three PWM channels available.

Thanks guys!

Everybody knows it's cool to have LEDs in your case, whether in strips or otherwise. It's even cooler to be able to control these, namely brightness if you only have one color. There are 5.25" bay control solutions, but as an owner of a case without such a bay, I'm looking for a different solution for brightness control. I have some experience using an Arduino to PWM a small LED around 1000Hz, but I'm looking for a bigger better solution for more LEDs and from a different PWM source. As an aerospace engineer, I don't know as much about semiconductors and their implementations as some of you guys out here, so I was hoping for some guidance on what I think is a pretty cool idea.

PWM motherboard fan headers provide usually a 25kHz PWM signal at 5v and 5mA from 0-100% duty cycle, something ideal for PWM fans to read and be controlled by. However, I think this PWM source would be ideal for LED control. The challenge is "amplifying" that PWM source to a 12V signal between 1-2A for a good number of LEDs. My experience tells me there should be a relatively simple implementation of a MOSFET or bipolar junction transistor to use the 5v signal to switch a 12v signal to power the lights, but I don't know what other details need to be considered here. I know this type of modulation exists in LED drivers and stepper motor drivers, but I'm looking to implement it in this case.

I hope somebody who has more semiconductor experience can lend some guidance, I think this would be a super cool thing to have implemented because then you could for instance set up a profile in speedfan or control it manually or all these things, and even control an RGB strip if you have three PWM channels available.

Thanks guys!