-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Upgrading mosfets?

- Thread starter saturn

- Start date

- Joined

- Sep 25, 2015

Unless you have a complete schematic, I would not end think about it.

The conversion circuit is highly tuned...and if done properly will take into account the characteristics of the FET.

You would get more improvement by upgrading the capacitors. Same value, same voltage, lower ESR.

The conversion circuit is highly tuned...and if done properly will take into account the characteristics of the FET.

You would get more improvement by upgrading the capacitors. Same value, same voltage, lower ESR.

Unless you have a complete schematic, I would not end think about it.

The conversion circuit is highly tuned...and if done properly will take into account the characteristics of the FET.

You would get more improvement by upgrading the capacitors. Same value, same voltage, lower ESR.

What! I love the part about the iPhone.

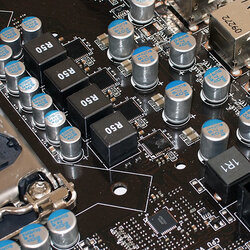

I would say, people have but it would be to overclock older systems. Modern motherboards have very well designed DC-DC power converter systems. Today's VRMs are a high degree better than some generations ago. Now that we have I2C and SMBus controllers, the CPU and VRM can communicate in a faster and more controlled environment. The faster ADCs that are used today enable VRMs to sample feedback signals faster, and tune the PWMs to be as clean as possible. Furthermore, the materials used for today's inductors and capacitors cause little impedance and lower power dissipation. This in turn allows the system to have clean signals in the first place.

Also, you don't need a schematic.

Here is a old P55 motherboard with a bad VRM design that could not take 1.36v the VRM phase blew, this would be a good project for you.

P55 On A Budget: Five Core i5/i7 Motherboards For $100-$150 burned msi P55-CD53

http://www.tomshardware.com/reviews/budget-p55-motherboard,2436-15.html

http://www.tomshardware.com/reviews/budget-p55-motherboard,2436-15.html

Everything You Need to Know About The Motherboard Voltage Regulator Circuit

http://www.hardwaresecrets.com/ever...-the-motherboard-voltage-regulator-circuit/1/

P55 On A Budget: Five Core i5/i7 Motherboards For $100-$150 burned msi P55-CD53

http://www.tomshardware.com/reviews/budget-p55-motherboard,2436-15.html

http://www.tomshardware.com/reviews/budget-p55-motherboard,2436-15.htmlEverything You Need to Know About The Motherboard Voltage Regulator Circuit

http://www.hardwaresecrets.com/ever...-the-motherboard-voltage-regulator-circuit/1/

- Thread Starter

- #7

What! I love the part about the iPhone.

I would say, people have but it would be to overclock older systems. Modern motherboards have very well designed DC-DC power converter systems. Today's VRMs are a high degree better than some generations ago. Now that we have I2C and SMBus controllers, the CPU and VRM can communicate in a faster and more controlled environment. The faster ADCs that are used today enable VRMs to sample feedback signals faster, and tune the PWMs to be as clean as possible. Furthermore, the materials used for today's inductors and capacitors cause little impedance and lower power dissipation. This in turn allows the system to have clean signals in the first place.

Also, you don't need a schematic.

I figured much, most of my knowledge with low level hardware is outdated and dose not apply today. When I got my x48 lanparty board I took off the VRM heatsink and thought to me self, what is all this crap? This sure it odd...

I'm more then sure that on a old socket 1//3/4/5 system it could be done maybe a P6 system too. I know I done it in the past to old video cards but that a hole different ballpark.

I'looks like the VRM's on newer stuff is more complex than it was in the past.

I'm sure that the throttling system used on asrock and asus motherboards would go nuts too.

To add a little bit more, ASUS, Gigabyte, MSI, and just about all the other big companies have a single supplier to develop better chokes, caps, and FET drivers for these power rails. As the CPU/GPU became more complex, the rise of a more controlled power rail rose as well.

Can you elaborate a bit on the single supplier thing? ASUS/Giga/MSI/ASrock etc, use different brand PWM controllers (some from IR, others not), FETs, Chokes, etc. Even throughout their lines its different (why put an expensive IR digi PWM controller on a budget board?). Do these all come from a single supplier but different companies strap their names on the ICs?

- Thread Starter

- #10

I think he means that they out source the development of the vrms. The IC's, chokes and mosfets all come form different suppliers but with the ratings specified by the developers/engineers.

typically and this could be outdated too, the engineers specifi the rating for the part then someone else gets with the supplier/s And buys the parts. And bigger companies often have one or a few parts suppliers.

typically and this could be outdated too, the engineers specifi the rating for the part then someone else gets with the supplier/s And buys the parts. And bigger companies often have one or a few parts suppliers.

Last edited:

The VRM world is rapidly changing with the introduction of pure digital controllers. We have seen them working for awhile now, but several companies have been working on these types of controllers. Chil has been absorbed by IR? DigiVRM is an IR product, but branded for ASUS. Same goes with Giga's Dr.MOS, IRS makes these. NCP makes a lot of VRs for Nvidia and Intel Server side. TI, MAX, OnSemi, and a bunch of other companies are backing out or introducing unique lineups, that include the inductor and capacitance.

This all started around the time Intel realized that VRMs were causing issues with their CPUs. None of the top companies that created these ICs wanted to get involved in trying a new technology and trying to sell millions of units to Dell/HP/ASUS...etc. So Intel created the VRM12 Spec that would initiate a need to move from the try and true analog VRMs to Digital VRMs. Once this change initiated, other companies started to become involved, those that had a stronger history in digital power rather than analog. Companies like TI had been born and raised in Analog, but NCP is somewhat of a new player (but they were bought by OnSemi).

Once VRM12 became the standard, all the major motherboard companies decided to start creating their own digital power circuit to attract customers. VRM12 came in right when UEFI became the standard, so basically we can think of the motherboard receiving a huge facelift. And this created a domino effect for all the ICs you see on the motherboard. Just about all of your ICs (including the VRMs and BIOS) communicate with each other using I2C/SMBus or something related to these protocols. Digital ICs communicating on a common bus allows for a high degree of configuration, and this circles back to OEM companies wanting their own VRMs. Specific features could be integrated that is only seen on their boards. Not exactly how things have turned out, but we are in 2nd/3rd generation of these types of motherboards, so a lot can still change.

With digital VRMs, sampling speeds have increased, this means that all the components on the power rails can be examined individually to a higher degree. We can see the ripples of capacitors causing overshoot and undershoot to occur, falsely tripping the OCV and UCV. We can also drive FETs faster! Lets say you wanted to build an ePower board, well this would be very difficult to achieve these days unless you buy in bulk. Thats because these newer components are made to reduce the issues just stated. The inductors provide a silky smooth current, and have little power dissipation. The capacitors are made of better materials to create a tighter tolerance and reduce ripple. The gates of FETs are fast (0.5ns to 2ns), but the capacitance due to the thin large surface area gate, is very very low (very important for driving FETs at fast speeds!).

All in all, it comes down to OEMs protecting their new power rails. They want to make it more difficult for others to obtain the same performance. Because in reality, these circuits are super simple, and do not change much. A resistor here or there to create different tolerances, thats it. The same inductor size and capacitance will be there for just about each generation. The materials in these components is the key though.

This all started around the time Intel realized that VRMs were causing issues with their CPUs. None of the top companies that created these ICs wanted to get involved in trying a new technology and trying to sell millions of units to Dell/HP/ASUS...etc. So Intel created the VRM12 Spec that would initiate a need to move from the try and true analog VRMs to Digital VRMs. Once this change initiated, other companies started to become involved, those that had a stronger history in digital power rather than analog. Companies like TI had been born and raised in Analog, but NCP is somewhat of a new player (but they were bought by OnSemi).

Once VRM12 became the standard, all the major motherboard companies decided to start creating their own digital power circuit to attract customers. VRM12 came in right when UEFI became the standard, so basically we can think of the motherboard receiving a huge facelift. And this created a domino effect for all the ICs you see on the motherboard. Just about all of your ICs (including the VRMs and BIOS) communicate with each other using I2C/SMBus or something related to these protocols. Digital ICs communicating on a common bus allows for a high degree of configuration, and this circles back to OEM companies wanting their own VRMs. Specific features could be integrated that is only seen on their boards. Not exactly how things have turned out, but we are in 2nd/3rd generation of these types of motherboards, so a lot can still change.

With digital VRMs, sampling speeds have increased, this means that all the components on the power rails can be examined individually to a higher degree. We can see the ripples of capacitors causing overshoot and undershoot to occur, falsely tripping the OCV and UCV. We can also drive FETs faster! Lets say you wanted to build an ePower board, well this would be very difficult to achieve these days unless you buy in bulk. Thats because these newer components are made to reduce the issues just stated. The inductors provide a silky smooth current, and have little power dissipation. The capacitors are made of better materials to create a tighter tolerance and reduce ripple. The gates of FETs are fast (0.5ns to 2ns), but the capacitance due to the thin large surface area gate, is very very low (very important for driving FETs at fast speeds!).

All in all, it comes down to OEMs protecting their new power rails. They want to make it more difficult for others to obtain the same performance. Because in reality, these circuits are super simple, and do not change much. A resistor here or there to create different tolerances, thats it. The same inductor size and capacitance will be there for just about each generation. The materials in these components is the key though.

Are all the phases the same now digital, just the Amps per phase and number of phases different? I can't find any information on what the new boards are using for components drivers, FETs, chokes, past 2012 it looks like technology has halted?

Last edited:

Wingman you have it correct, there isn't much variation outside of number, current, and if they use a double phase (12phases running off of 6phases produced by the VRM).

Now for the components, like I said these are produced by a single supplier for each company. That means that ASUS uses one company, Gigy another, and so forth. This isn't the case with ALL MOBO OEMs but its for the big players: ASUS/ASROK, Gigabyte, MSI, and EVGA. The information for these parts cannot be found online due to NDA/buisness agreements, and the like.

Now for FETs and Drivers, this is a bit different. ASUS and Gigabyte use exclusively the VRM companies product, due to some special features/similar compatibility. Other companies will just grab off the shelf/high volume types but they are not fitted to their needs.

Now for the components, like I said these are produced by a single supplier for each company. That means that ASUS uses one company, Gigy another, and so forth. This isn't the case with ALL MOBO OEMs but its for the big players: ASUS/ASROK, Gigabyte, MSI, and EVGA. The information for these parts cannot be found online due to NDA/buisness agreements, and the like.

Now for FETs and Drivers, this is a bit different. ASUS and Gigabyte use exclusively the VRM companies product, due to some special features/similar compatibility. Other companies will just grab off the shelf/high volume types but they are not fitted to their needs.

I can find IR parts pretty easily among others (see my mobo reviews). Just takes looking at the numbers on it and googling.The information for these parts cannot be found online due to NDA/buisness agreements, and the like.

Though, not many are on there, that is for sure.

Thanks Geo for the info.

Similar threads

- Replies

- 21

- Views

- 1K