-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Member- designing a immersion, subzero system

- Thread starter CraigRochester

- Start date

What happens if that vacuum breaks catastrophically?which would require a full vacuum / 200 psi pressure vessel with crazy seals for the wires.

Don't misunderstand me, I would love to see this done, but the practicality of it is nill to me..(but its also not for me, nor my time, effort, and money.

- Joined

- Jun 28, 2012

roger that... I believe you this time. ;-)

I'm still mulling over using R-410A, which would require a full vacuum / 200 psi pressure vessel with crazy seals for the wires.

Have fun getting the permits

OP

- Joined

- Mar 19, 2016

- Thread Starter

- #47

Have fun getting the permits

I'll do it at my cabin in Maine

Maine Revised Statutes

§15102. Exemptions

.

.

.

2. Pressure vessels. This chapter does not apply to:

.

.

.

J. Pressure vessels that do not exceed:

(1) Five cubic feet in volume and 250 pounds per square inch gauge pressure;

(2) One and 1/2 cubic feet in volume and 600 pounds per square inch gauge pressure; or

(3) An inside diameter of 6 inches with no limitation on pressure; or [2003, c. 204, Pt. G, §1 (AMD).]

.

.

.

2. Pressure vessels. This chapter does not apply to:

.

.

.

J. Pressure vessels that do not exceed:

(1) Five cubic feet in volume and 250 pounds per square inch gauge pressure;

(2) One and 1/2 cubic feet in volume and 600 pounds per square inch gauge pressure; or

(3) An inside diameter of 6 inches with no limitation on pressure; or [2003, c. 204, Pt. G, §1 (AMD).]

- Joined

- Sep 7, 2013

I dunno... A chilled water loop sounds a lot less expensive and less risky right about now eh?

OP

- Joined

- Mar 19, 2016

- Thread Starter

- #50

Doesn't mean you'll find somewhere to sell the refrigerant and gauges to you

I'd have one of the HVAC techs I work with help me charge the rig.

I'm thinking making wiring penetrations through the steel that won't leak refrigerant may be a show stopper.

- - - Updated - - -

I dunno... A chilled water loop sounds a lot less expensive and less risky right about now eh?

I guess I need to rename the project again. What do you think of "Widow Maker"?

- Joined

- Jan 2, 2012

I think that you should go ahead and do the testing for this and give it a try.

I also think you should build your sons computer first. I have a feeling that by the time all the bugs are worked out of this system it will be ready for him to play Battlefield 14.

I also think you should build your sons computer first. I have a feeling that by the time all the bugs are worked out of this system it will be ready for him to play Battlefield 14.

- Joined

- Jun 28, 2012

I'd have one of the HVAC techs I work with help me charge the rig.

I'm thinking making wiring penetrations through the steel that won't leak refrigerant may be a show stopper.

- - - Updated - - -

I guess I need to rename the project again. What do you think of "Widow Maker"?

It will have to be hard line with a brazed connection, most likely.

Also, where's your phase change going to happen? It needs to be a refrigerant loop of some sort as phase change is how refrigerant cools.

OP

- Joined

- Mar 19, 2016

- Thread Starter

- #53

It will have to be hard line with a brazed connection, most likely.

Also, where's your phase change going to happen? It needs to be a refrigerant loop of some sort as phase change is how refrigerant cools.

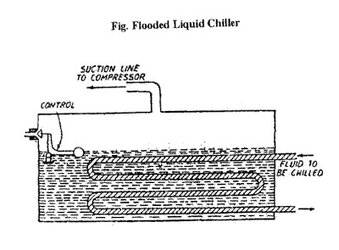

I'm looking into something like a "flooded barrel" chiller; where the bathtub is full (w/ head space) of R-410A. I'm still studying this system to understand the HT, but the phase change occurs in the head space where a float valve maintains vapor above a fixed level. I have no idea how I'd get all the HDMI, USB, etc connectors' penetrations through.

- Joined

- Sep 7, 2013

Careful with 410A... That crap needs some serious pressure just to cool stuff.

Personally, I'd look to use R134a but it's getting hard to find.

My dad still has 20lbs of R22A. That stuff cools real well

Personally, I'd look to use R134a but it's getting hard to find.

My dad still has 20lbs of R22A. That stuff cools real well

OP

- Joined

- Mar 19, 2016

- Thread Starter

- #55

Careful with 410A... That crap needs some serious pressure just to cool stuff.

Personally, I'd look to use R134a but it's getting hard to find...

I like the lower boiling point of R-410A @ -48C, R-134A is -26C (Amazon- R-134a Cylinder - 30 lb. $97). R-410A is common in window A/C units where I'll be able to get the compressor and condenser coil easily/cheaply.

Yes the box design will need to be about 350 psi (@ 100F) to not blow a safety relief. This pressure is getting out of my comfort zone and may be moot, as I can't see any practical way to get the ports out of the box.

- Joined

- Sep 7, 2013

I like the lower boiling point of R-410A @ -48C, R-134A is -26C (Amazon- R-134a Cylinder - 30 lb. $97). R-410A is common in window A/C units where I'll be able to get the compressor and condenser coil easily/cheaply.

Yes the box design will need to be about 350 psi (@ 100F) to not blow a safety relief. This pressure is getting out of my comfort zone and may be moot, as I can't see any practical way to get the ports out of the box.

Wonder if there is another refrigerant out there that will work without huge pressure?

Seem they don't mix. huh.

- Joined

- Jan 2, 2012

So this has turned into a hypothetical build now? What about your sons system?