- Joined

- Mar 19, 2016

Hi,

Craig here...

I'm an old guy who did overclocking before Al Gore invented the internet. My son asked me to help him with designing a water cooled Gaming PC and I got interested in going extreme on the design.

I'm researching:

Any tips, tricks or warnings much appreciated!

Craig here...

I'm an old guy who did overclocking before Al Gore invented the internet. My son asked me to help him with designing a water cooled Gaming PC and I got interested in going extreme on the design.

I'm researching:

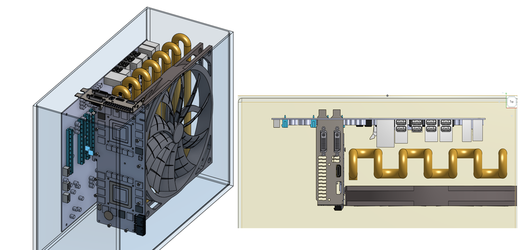

- "Direct Expansion (DX)" cooling. 2-phase in OC jargon

- Liquid Immersion- to address condensation

- Ammonia refrigerant to be "green" @ ~ -20C temps

- DX blocks on CPU & GPU

- DX coils throughout the water bath for forced convection cooling (liquid stirring) of other MB components

Any tips, tricks or warnings much appreciated!

Last edited: