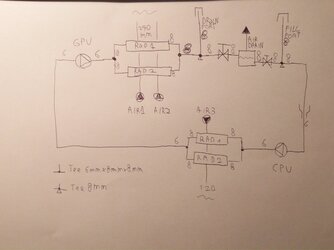

- Thread Starter

- #21

I have to agree with the above statements video avoid mixed metal loops. These tent to cause a lot of issues. It's also why aluminum rads are getting hard to find.

The port can be located anywhere it's easily accessible. Where it is in the loop isn't as important but some will say it should be after the pump so you can use the pump to drain the line. The issue with this is you can't use the pump to fill. On that note, NEVER run you pump dry, even for a few seconds.

Oh well. I will use one pump to fill and one to drain, I wasn't thinking about the drain. And ye, never run a pump dry, this should be stated more often.

I know that a 60 mm thick radiator made out of copper is way better in all of the ways you look at it, but hey, these aluminium rads are cheap as hell. I got all of them for less than 100$ and if I'm right they will perform similarly too 60mm thick rads, so even if it's aluminium, I should get good performances out of them.

Same thing applies for the waterblocks with integrated pumps. I know a single standalone pump may perform way better, just starting by the fact the pump itself heats up, but these are replacement parts for AIO units, they are bloody cheap, more than a pump and a waterblock.

Id cooling is the first one to make a full AIO system for GPU + CPU, called Hunter Duet, with a single 2.120X30 aluminium rad. They are chinese, but they got positive reviews. Or, I consider positive a review stating that it's ALMOST able to support a full overclocked system in silence, which is what I expect from a single radiator like that and something good for an expense of 170$ which comes ready to mount. When they released the blocks singularly, I realized how much bang for your bucks they give you. Also, they are making the first AIO kit for SLI cards.

I'm sorry, I only look at performance/price rateo when it comes to PC, I'm cheap ******* and I know it

@Lochekey May I ask you to further explain why I should put them in series, performance wise? I think I should maximize flow, not prevalence, for a radiator.