Hi. I'm new here.

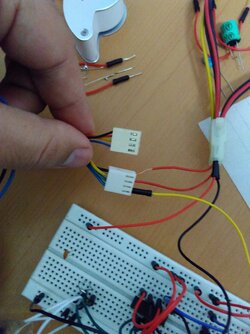

I built a PWM controller according to http://www.overclockers.com/forums/...r-4-wires-PWM-fan/page2?p=6473318#post6473318

It works well on a led and on an Intel supplied Nidec CPU fan. The reason for doing it all though was to have a controllable strong fan so I bought a Delta TFC1212DE off ebay. Sadly, the Delta fan always runs at full speed and doesn't respond to the PWM signal from the circuit. I tried an inverted signal also, nothing.

I tried many things but I'm out of ideas at this stage.

What can be the reason for the fan not to respond to the PWM signal at all?

Thanks!

I built a PWM controller according to http://www.overclockers.com/forums/...r-4-wires-PWM-fan/page2?p=6473318#post6473318

It works well on a led and on an Intel supplied Nidec CPU fan. The reason for doing it all though was to have a controllable strong fan so I bought a Delta TFC1212DE off ebay. Sadly, the Delta fan always runs at full speed and doesn't respond to the PWM signal from the circuit. I tried an inverted signal also, nothing.

I tried many things but I'm out of ideas at this stage.

What can be the reason for the fan not to respond to the PWM signal at all?

Thanks!

Last edited: