Hello everyone! I am in the midst of custom building a gaming computer and thought I'd share my progress with this lovely forum. This build is still a work in progress but I aim to have it done by August 4th for the QuakeCon event in Dallas. So let's get the good stuff started!!

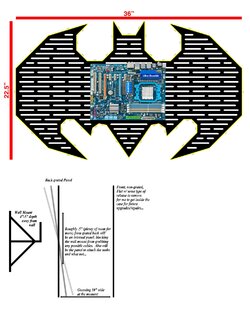

The 'End Goal' for this build is a wall mounted 'Batman' shaped gaming computer/case that will glow yellow and look AWESOME above my desk for when I play games. Did I mention AWESOME!?

Equipment:

• Plasma Cam

• Press Break

• PemSerter

• TIG Welder

• Drill / Drill Bits

• Small Angle Grinder

• Electric Sander

○ 120 and 220 Grit Sand Paper (roughly 20 sheets is what I used)

• Die Grinder

○ 40, 60, 80 Grit Sanding Tips (roughly 10 sheets is what I used)

• 1/8" Aluminum Sheets

• Rust-Oleum Truck Bed Coating Black Spray Paint (with and without built in primer)

• Foam

• Exacto Knife

• Ruler

• Protractor

• Sponge Brushes

• Paint Brushes

• 6/32" Sheet Metal Counter Sunk Scres / Nuts

~~possibly more to come~~

Software:

• AutoCAD

• Adobe Illustrator

Computer Components:

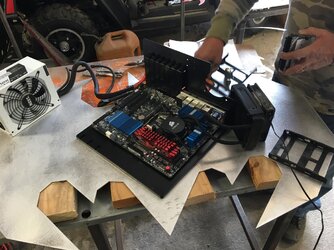

• Lian-Li Motherboard Tray - Black

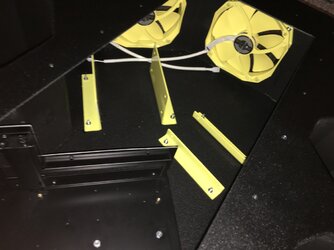

• Phanteks PH-F140HP - 140mm Fan (6 for this build)

• 140mm Black Anodized Aluminum PC Fan Grill (6 for this build)

• ModMyToys Anodized Illuminated 22mm Momentary Switch - Power Symbol Black / White

• HDMI to DVI Cables

• Pactech 4 Pin Molex Connector

• Right Angle DVI Adapters

• Nvidia 960 Graphics Card

~~possibly more to come~~

Table of Contents

Thank you for checking out my build and coming along for the journey. If you're coming to QuakeCon, come and check out the final version in the BYOC area. For those not coming to QuakeCon, I'll post images of the event and my computer being there!

The 'End Goal' for this build is a wall mounted 'Batman' shaped gaming computer/case that will glow yellow and look AWESOME above my desk for when I play games. Did I mention AWESOME!?

Equipment:

• Plasma Cam

• Press Break

• PemSerter

• TIG Welder

• Drill / Drill Bits

• Small Angle Grinder

• Electric Sander

○ 120 and 220 Grit Sand Paper (roughly 20 sheets is what I used)

• Die Grinder

○ 40, 60, 80 Grit Sanding Tips (roughly 10 sheets is what I used)

• 1/8" Aluminum Sheets

• Rust-Oleum Truck Bed Coating Black Spray Paint (with and without built in primer)

• Foam

• Exacto Knife

• Ruler

• Protractor

• Sponge Brushes

• Paint Brushes

• 6/32" Sheet Metal Counter Sunk Scres / Nuts

~~possibly more to come~~

Software:

• AutoCAD

• Adobe Illustrator

Computer Components:

• Lian-Li Motherboard Tray - Black

• Phanteks PH-F140HP - 140mm Fan (6 for this build)

• 140mm Black Anodized Aluminum PC Fan Grill (6 for this build)

• ModMyToys Anodized Illuminated 22mm Momentary Switch - Power Symbol Black / White

• HDMI to DVI Cables

• Pactech 4 Pin Molex Connector

• Right Angle DVI Adapters

• Nvidia 960 Graphics Card

~~possibly more to come~~

Table of Contents

Phase 12 - Additional Details

Phase 13 - New Computer Components

Phase 14 - Finalization

~~possibly more to come~~Thank you for checking out my build and coming along for the journey. If you're coming to QuakeCon, come and check out the final version in the BYOC area. For those not coming to QuakeCon, I'll post images of the event and my computer being there!

Last edited:

Fantastic progress!!

Fantastic progress!!