- Joined

- Apr 26, 2012

- Location

- New York, USA

I've seen that done before, so I don't see why not?

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

I learned something important today:

Don't build a custom loop for the first time while you're hung over.

Today I have:

Installed one of the radiator fans backwards, had to remove and reinstall the radiator and fans.

Gouged the hell out of the other radiator because I grabbed the wrong screws. (minor cosmetic issue only)

Gouged some screws pretty bad by using the wrong screwdriver

Realized I had installed both radiators and forgot to replace the rubber shipping plugs with the actual threaded plugs, have to remove them AGAIN because I can't get at all the ports.

Hurt my fist in an inexplicable impact with a wall.

Time for a break.

Never celebrate before the project. Lets hope you didn't damage the rad. Leak test the proper way with only the pumps with power.

Take your time. Its not a race. Just a very cool (pun intended) hobby.

Here's hopin! But hey, learning all this is part of the fun. Once finished, the satisfaction will be that much greater.Man, sorry about your luck Exadeuce. You're absolutely right though. That is exactly why we leak test with out power to anything but the pump. Hopefully you have it all figured out now and don't have any other hang-ups.

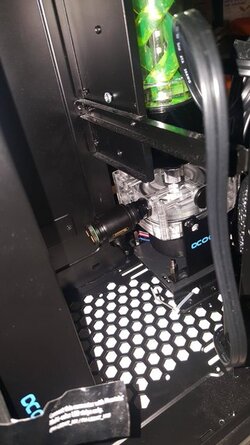

The short straight piece was definitely the cause of the fountain. The tube was just too short and didn't actually form a seal, instead forming a water jet!Do you plan on putting the short straight piece back on now that you know it wasn't the culprit? I think it looks better that way personally.

Yes. I could flip the U-tube towards the left or even have it vertical. I think going over the RAM does look better, but that could be a pain down the road some day.Also, it looks like you might have some issues getting to your ram sticks with your lines run that way or is that just the angle of the picture?

I would have probably gone from the CPU block out to the VRM on the left, then from the VRM out on top to the radiator, but it is more open the way you have it. All personal preference and how much time and patience you have.

Yeah, even the couple hours this has been running there's noticeably fewer bubbles. I also tilted the case all around and a TON of bubbles came spewing out of the top radiator.The bubbles will dissipate after a few days, don't worry about it too much.

I really like the classic helix res+matching tube color. Reminds me of those old school neon green coolant builds, very slick.