Hello,

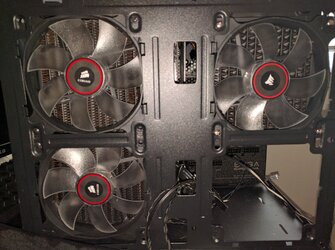

After reading large amounts of content on this site, i finally purchased and built my cpu loop in my new Fractal Node804 case.

I am having a slight issue however that i am hoping someone can shed some advice on.

The issue is regarding the Micro tube res and DDC pump.

I am currently trying to bleed the system, however it seems like due to the short length of the tube res, the air is getting sucked back into the pump before it has time to surface..

It has been running for about 2 hours with the 1 fill cap off and it has gotten a little better but still no where near perfect.

Video attached..

Out of curiosity i did boot the system and gamed for a while and temps went from 80c on air to 54c on h20 which is great but i feel the air in the system will be screwing my results a little.. plus the pump is still noisy due to the air..

Is there any way to resolve this ? or get rid of some of the turbulence or air being sucked right back into the pump ? I see some of the tube reservoirs come with some foam piece that sits on top of the inlet to the pump section? i do not have this.. wondering if i could make one or if it would help allow some of the air to surface rather then get sucked into the pump..

specs: intel i5 6400 @ 4.2Ghz

GTX 970 Evga acx2.0

8gb gksill ripjaw

Thanks in advance!!

After reading large amounts of content on this site, i finally purchased and built my cpu loop in my new Fractal Node804 case.

I am having a slight issue however that i am hoping someone can shed some advice on.

The issue is regarding the Micro tube res and DDC pump.

I am currently trying to bleed the system, however it seems like due to the short length of the tube res, the air is getting sucked back into the pump before it has time to surface..

It has been running for about 2 hours with the 1 fill cap off and it has gotten a little better but still no where near perfect.

Video attached..

Out of curiosity i did boot the system and gamed for a while and temps went from 80c on air to 54c on h20 which is great but i feel the air in the system will be screwing my results a little.. plus the pump is still noisy due to the air..

Is there any way to resolve this ? or get rid of some of the turbulence or air being sucked right back into the pump ? I see some of the tube reservoirs come with some foam piece that sits on top of the inlet to the pump section? i do not have this.. wondering if i could make one or if it would help allow some of the air to surface rather then get sucked into the pump..

specs: intel i5 6400 @ 4.2Ghz

GTX 970 Evga acx2.0

8gb gksill ripjaw

Thanks in advance!!

! The hard tubing looks pretty slick too.... might give that a try..

! The hard tubing looks pretty slick too.... might give that a try..